12.

Assembly and adjustments

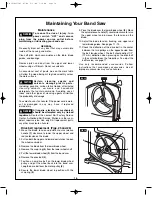

Replace the blade (Fig. 13)

Blade teeth are sharp. Use care when

handling a band saw blade.

It is possible to replace the blade with the table in place,

however, it may be easier to remove the table before

replacing the blade. If you do not remove the table,

remove the plastic table inset and pull the table

extension out so that it does not block the slot in the

table before removing or installing the blade.

1. Loosen the fence clamp and remove the fence from

the table.

2. Pull on the upper and lower door latches to open the

wheel cover door.

3. Move the blade tension adjustment quick release

handle

(1)

clockwise to lower the upper wheel and

reduce tension on the blade.

4. Remove the old blade

(2)

. Slide the blade out and

away from the upper and lower blade guides

(3)

(and

through the slot in the table if you did not remove it).

5. Put the new blade in position around the upper and

lower wheels and between the upper and lower blade

guides

(3)

.

6. Center the blade on the upper and lower wheels.

Turn the upper wheel slowly to check the position of

the blade.

7. Move the blade tension adjustment quick release

handle

(1)

counterclockwise to increase the tension

on the blade.

8. Make sure the blade is still centered on the upper and

lower wheels and that it moves freely through the

blade guides.

9. The blade must be adjusted properly before operating

the saw:

a. See Blade tension adjustment (page 11).

b. See Blade tracking adjustment (page 11).

c. See Blade guide adjustment (page 12).

FIG. 13

1

2

3

3

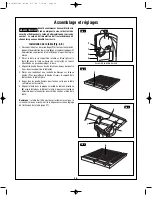

Blade guide adjustment

The upper and lower blade guides and support bearings

(located above and below the table) keep the blade

moving in a straight line during operation. These guides

must be checked and adjusted before each use and

after changing the blade.

Note:

Make sure the blade tension and tracking are

properly adjusted before adjusting the upper and lower

blade guides.

Adjust the upper blade guide (Fig. 14–16)

1. Make sure the upper blade guide assembly

(1)

is at

right-angles to the blade

(2)

. If not:

a. Loosen the screw

(3)

and rotate the assembly until it

is perpendicular to the blade.

b. Tighten the screw

(3)

.

2. Loosen the support bearing screw

(4)

and move the

support bearing

(5)

forward or backward until the

bearing is 1/32" (0.8 mm) behind the blade. Tighten

the screw

(4)

.

3. Loosen the left and right blade guide screws

(6)

and

move the guides

(7)

as close to the blade as possible

without pinching it. Using a feeler gauge (not

provided), make sure the space between each guide

and the blade measures 0.02" (0.5 mm). Tighten the

screws

(6)

.

FIG. 14

3

2

1

WARNING

!

SM 2610957105 05-08 6/5/08 7:39 AM Page 12