11.

Assembly and adjustments

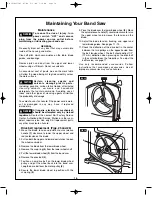

Blade tension adjustment (Fig. 11)

A change in blade width or type of material being cut will

affect the blade tension. If the blade tension is too loose,

the blade may slip on the wheels. If the blade is too

tight, the blade may break.

1. Turn the blade tension knob

(1)

clockwise, to raise

the upper blade wheel

(2)

and increase the tension

on the blade. The blade should be tight on the wheel,

but do not overtighten the blade.

2. Turn the blade tension knob

(1)

counterclockwise to

lower the upper blade wheel

(2)

and reduce the

tension on the blade.

Blade tracking adjustment (Fig. 11 and 12)

Check for proper blade tension before making any

blade tracking adjustments.

1. Rotate the upper blade wheel

(2)

clockwise and

check the position of the blade on the wheel. The

blade should remain in the center of the wheel.

a. If the blade moves toward the front of the wheel,

loosen the blade tracking lock knob

(4)

and turn the

blade tracking knob

(3)

slightly clockwise. At the

same time, turn the upper wheel

(2)

until the blade is

centered.

b. If the blade moves toward the back edge of the

wheel, turn the blade tracking knob

(3)

slightly

counterclockwise. At the same time, turn the upper

wheel

(2)

until the blade is centered.

2. Tighten the blade tracking lock knob

(4)

when you are

finished making adjustments.

3. Check the position of the blade on the lower wheel. If

the tracking is off, continue adjusting the blade until it

sits properly on both wheels.

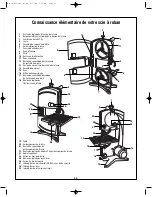

FIG. 11

1

FIG. 12

4

3

2

SM 2610957105 05-08 6/5/08 7:39 AM Page 11