16

5.3 - USE’S FIELDS

The dipping blender has been designed

to blend, fruit, vegetables, meat, food-

stuffs in general not frozen and in any

case soft.

The dipping blender has not been de-

signed to work chemicals, sewages,

glues and anything that is not strictly

food.

Even if designed to blend also hot prod-

ucts, it is recommended to operate with

products at a temperature below 70 de-

grees C. always for a short lapse of

time (maximum 10 minutes).

Blending:

Use of the shaft

(Fig. n°34).

Fruit, vegetables, meat, food in general

as long as mixed in some liquid solu-

tion.

Food pieces must have maximum di-

mensions of a nut (3x3x3 cm cubes as

long as without bones or stones and as

long as they are not too hard and con-

sistent).

starts at maximum speed. Be aware of

the counterblow that the engine’s

power can provoke in the hand and in

the wrist when gripping the machine

tightly.

-

If the machine has a speed variator,

after the engine has started, work on

the speed variator’s handle (4) with

the other hand and check the correct

its functioning

-

Check if the machine starts even

without pressing the button (1). In

this case, give up the test and call

the producer immediately.

2-Speed variator’s handle

1-Switch on

Fig. n°34

Fig. n°33

9

ture reference

(Fig. 14)

.

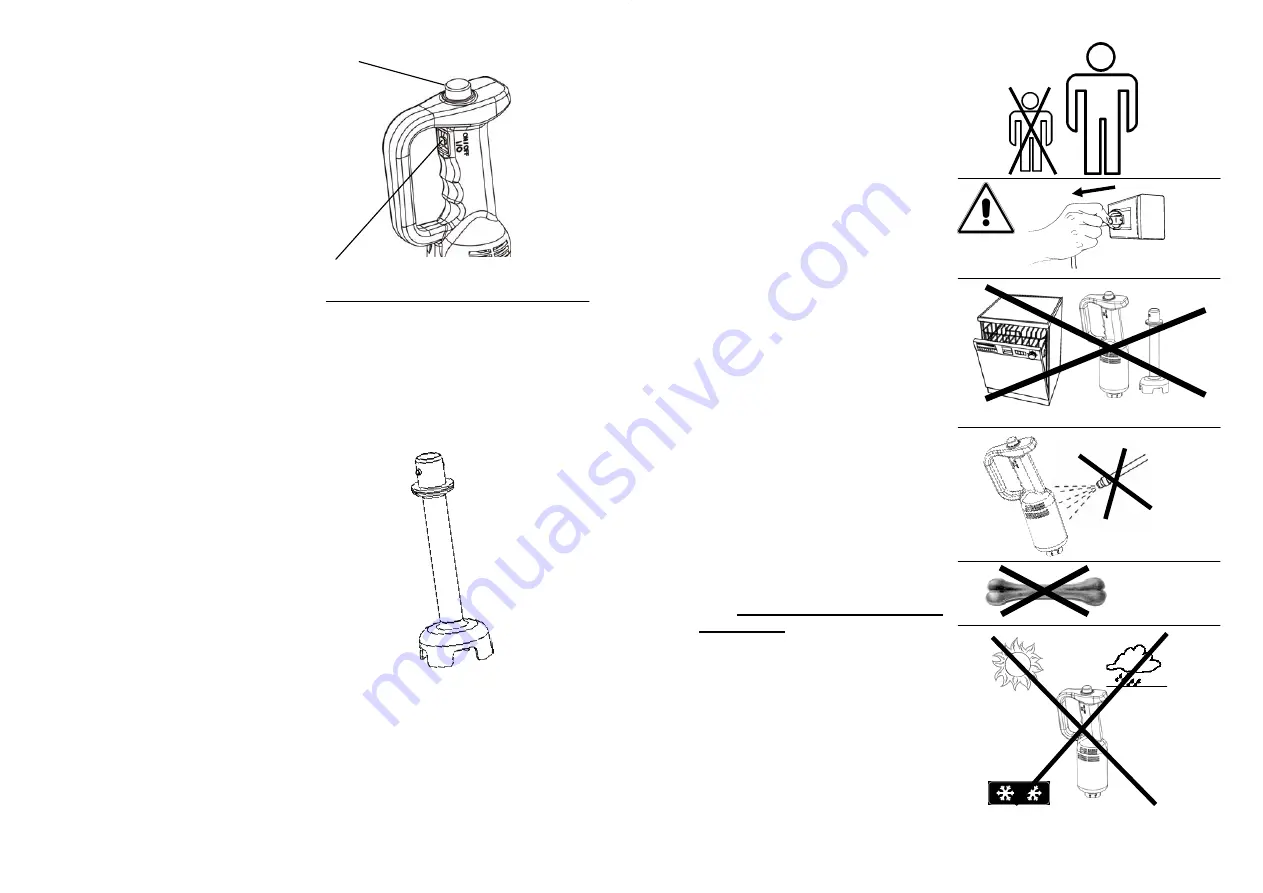

The dipping blender must be used

only by trained members of staff,

who must know the safety rules con-

tained in this manual perfectly.

In case of staff turn-over, please

proceed to train the new members

of staff in timely fashion.

Do not allow children, incompetents

or untrained members of staff to use

the blender (Fig. 15).

Before carrying out any cleaning or

maintenance task, unplug the ma-

chine from the electrical feeding net-

work (Fig. 16).

Before replacing accessories, un-

plug the machine from the electrical

feeding network (Fig. 16).

When intervening for ordinary main-

tenance or cleaning, carefully evalu-

ate risks.

Focus your attention on the opera-

tions in course during the use, main-

tenance and cleaning.

To clean the machine, follow care-

fully the instructions of the chapter

“Ordinary cleaning”.

Do not wash the blender by means

of the dishwasher or water jets (Fig.

17-18).

The dipping blender has been de-

signed to blend fruit, vegetables and

meat

(unfrozen and without bones

or stones)

(Fig. 19), and anyhow

food that is not particularly hard or

resistant to be processed. Any other

use is to be considered improper

and therefore dangerous.

Dry the machine’s body and the

used accessories after having

cleaned them.

Do not expose the blender to nox-

ious agents such as the sun, the

rain, splashes, humidity, frost (Fig.

20).

Fig. n°17

Fig. n°18

Fig. n°19

Fig. n°15

Fig. n°16

Fig. n°20