adjusting machine to your fabric

Straight-Stitch Settings

Stitch-

Width

Dial

Needle-

Position

Ring

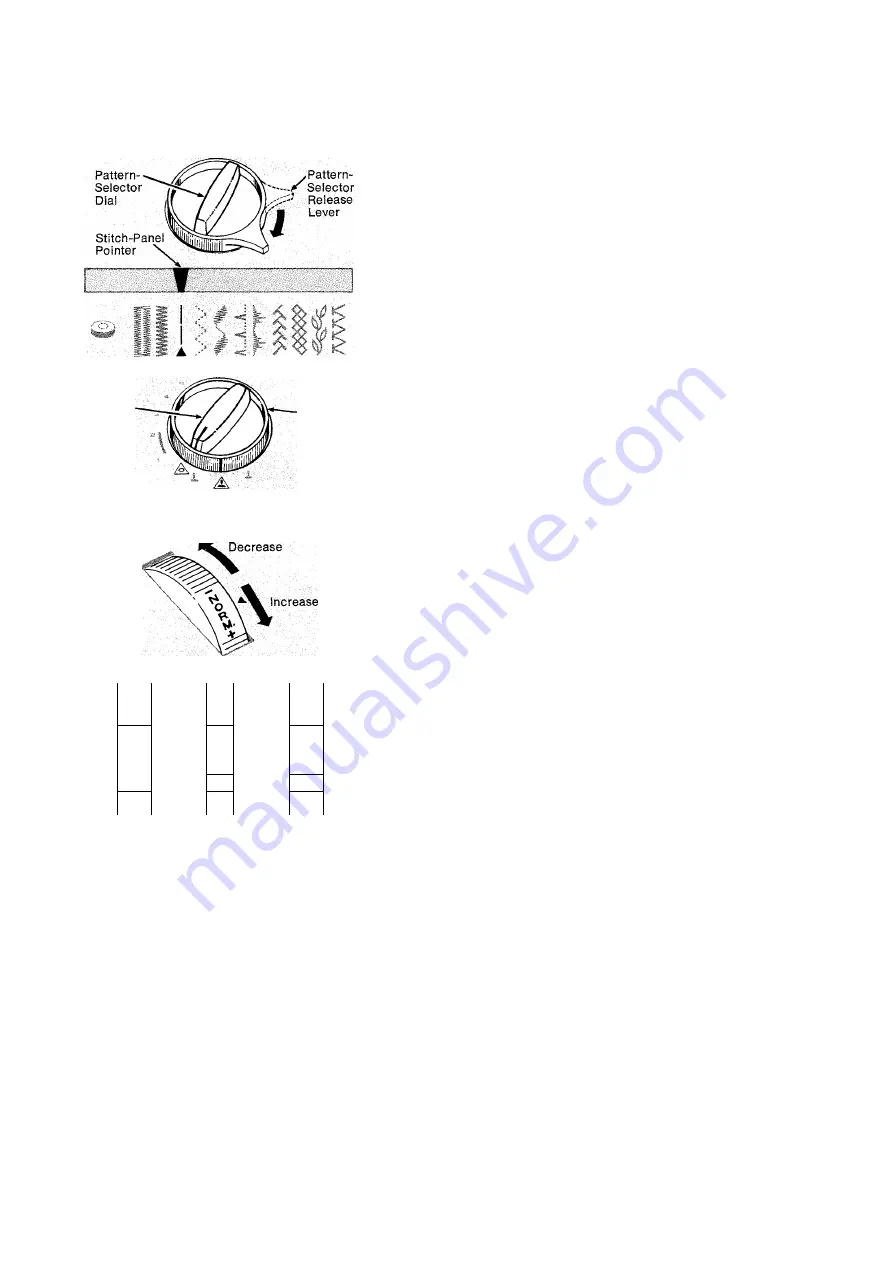

SETTING CONTROLS

1. Set pattern-selector release lever by turn

ing it clockwise until it locks in place. If

lever fails to lock, turn hand wheel slightly

and reset lever.

NOTE:

Do not attempt to turn pattern-

seiector release lever after it is locked in

place. It repositions itself when you start

the machine or turn the hand wheel.

2. Turn pattern-selector dial until stitch-panel

pointer is above | setting.

3. Turn stitch width dial to and turn needle

position ring to (center).

4. Attach straight-stitch foot and straight-

stitch plate (see pages 4 and 5).

NOTE:

When alternating between straight and

zig-zag stitching use the zig-zag foot and zig

zag plate, and set pattern selector on zig-zag

setting

I .

1 1

1 ri

-------

■■

1

N

1

i

1 i

■

H i

j

R

1 1

1

|_H_|

j i

J j

Pressure Dial

REGULATING PRESSURE

The pressure dial regulates the pressure that

the presser foot exerts on the fabric. The NORM

(normal) setting can be used for sewing a wide

variety of fabrics of different weight and texture.

Intermediate settings, above and below NORM,

are also provided. Generally

lighter than normal

pressure is best for thick, soft fabrics. See

page 45 for adjusting pressure when sewing

knits.

Lower the presser foot before setting pressure.

• To increase pressure, turn dial from NORM

toward MAX.

• To decrease pressure, turn dial from NORM

toward DARN.

•

• For darning, set dial on DARN.

14

Instrukcje obsługi maszyn do szycia firm Polskich jak i zagranicznych np. Singer Toyota Pfaff Gritzner Łucznik Arka