39

10.5 Unscheduled maintenance

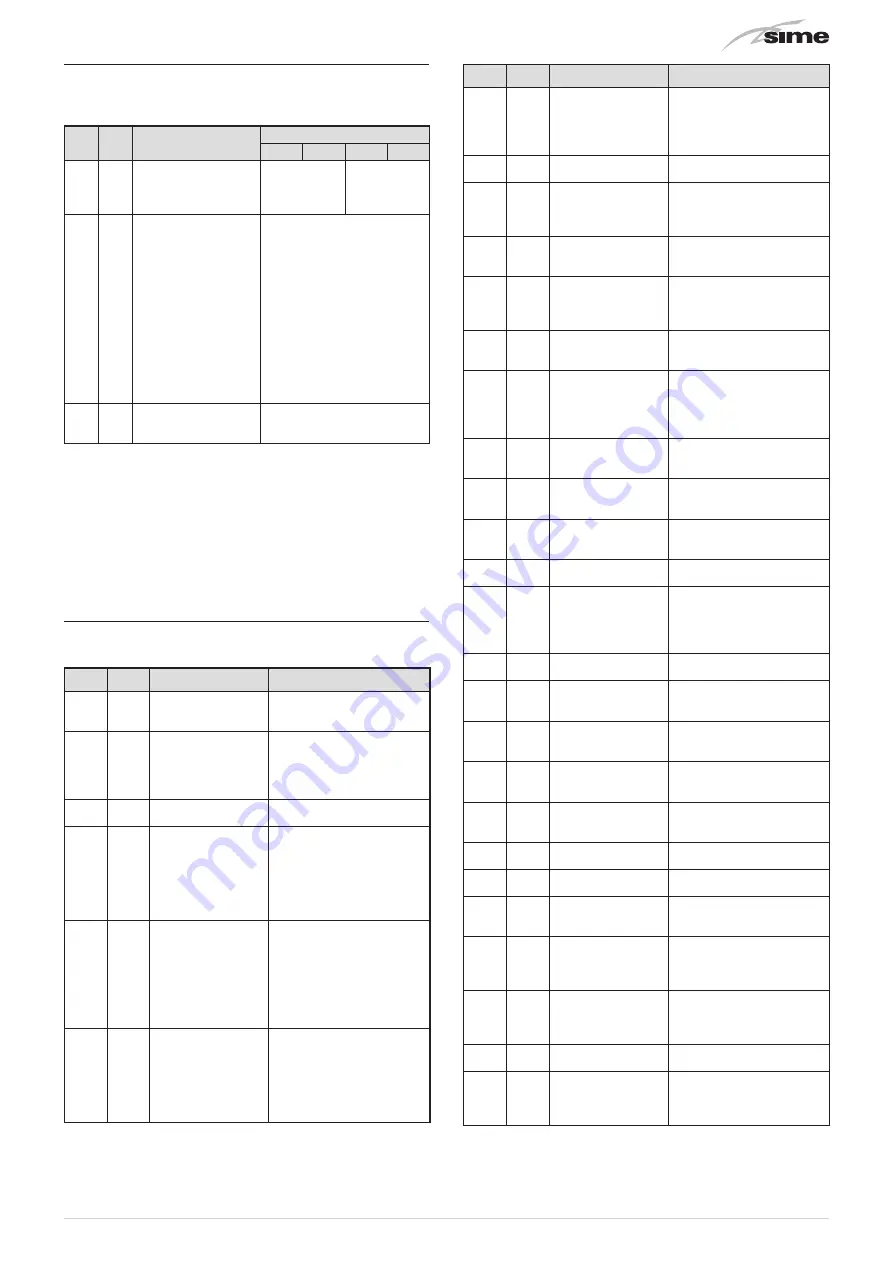

If replacing the

electronic board

, the user MUST set the

parameters as indicated in the table.

Type No. Description

Setting for

Brava Slim HE R

20 R i 20 R e 40 R i 40 R e

PAR

01

Index showing boiler

power in kW

1 = 20; 2 = 30; 3 = 35;

4 = 40

1

4

PAR

02

Hydraulic

configuration

0 = rapid

1 = storage tank with

thermostat or heating

only

2 = hot water tank with

sensor

3 = bithermic

4=instant with solar

power input

5 = open vent

6 = boiler with heat

pump

1

PAR

03

Gas Type Configuration

0 = NATURAL GAS; 1 =

UNIVERSAL LPG

0 or 1

To enter "

"refer to the indications

provided in the specific section.

Once the parameters in the table have been set, you must carry

out the entire phase of "

" described

in the specific section.

If the

gas valve

and/or the

ignition/detection electrode

, and/or the

burner

, and/or the

fan

are replaced, the user must still carry out

the entire phase of "

" described in

the specific section.

10.6 Possible faults and solutions

LIST OF MALFUNCTION/FAULT ALARMS

Type

No.

Fault

Solution

ALL

02

Low water pressure

in system

- Restore pressure

- Check for any leaks in the

system

ALL

03

High water pressure

in system

- Empty the system via the

drain valve on the hydraulic

assembly and bring the

pressure to approximately

1.2 bar (120 kPa)

ALL

05

Delivery sensor fault - Check connections

- Replace the sensor

ALL

06

No flame detection

- Check the integrity of the

electrode and check that it

is not grounded

- Check gas availability and

pressure

- Check the integrity of the

gas valve and the card

ALL

07

Sensor or safety

thermostat

intervenes

- Check the sensor or

thermostat connections

- Deaerate the system

- Check the bleed valve

- Replace the sensor or the

thermostat

- Check that the pump

impeller is not blocked

ALL

08

Fault in the flame

detection circuit

- Check the integrity of the

electrode and check that it

is not grounded

- Check gas availability and

pressure

- Check the integrity of the

gas valve and the card

Type

No.

Fault

Solution

ALL

09

No water circulating

in the system

- Check the rotation of the

pump rotor

- Check the electrical

connections

- Replace the pump

ALL

11

Gas valve modulator

disconnected

- Check the electrical

connection

ALL

12

Incorrect

configuration of

the open /sealed

chamber

- Set the parameter PAR 04

(Combustion configuration)

to 0

ALL

13

Smoke probe

intervention

- Replace the smoke probe

- Contact the Technical

Assistance Centre

ALL

14

Smoke probe fault

- Replace the smoke probe

- Check the electrical

connection of the smoke

probe

ALL

15

Fan check cable

disconnected

- Check the connection cable

between the fan and the

board

ALL

18

Condensate level

fault

- Check for any clogging in

the pipe which takes the

condensate to the siphon

- Check that the siphon is not

clogged

ALL

28

Maximum number of

consecutive resets

reached

- Contact the Technical

Assistance Centre

ALL

30

Return sensor (SR)

fault

- Replace the return probe

- Contact the Technical

Assistance Centre

ALL

37

Fault due to low

network voltage.

- Check with tester

- Contact network provider

(ENEL)

ALL

40

Incorrect network

frequency detected

- Contact network provider

(ENEL)

ALL

41

Flame loss more

than 6 consecutive

times

- Check the detection

electrode

- Check the gas supply (open

valve)

- Check mains gas pressure

ALL

42

Button fault

- Check that buttons are

working

ALL

43

Open Therm

communication fault

- Check the electrical

connection of the remote

control

ALL

62

Self-calibrating

procedure is required

- Carry out the self-

calibrating procedure (see

the specific section)

ALL

72

Incorrect positioning

of the delivery sensor

- Check that the delivery

sensor is attached to the

delivery pipe

ALL

77

EV2 SGV current

max/min absolute

limits error

- Contact the Technical

Assistance Centre

ALL

78

EV2 SGV current

upper limit error

- Contact the Technical

Assistance Centre

ALL

79

EV2 SGV current

lower limit error

- Contact the Technical

Assistance Centre

ALL

80

Fault on the valve

control logic line/

valve cable damaged

- Check the valve cable

- Contact the Technical

Assistance Centre

ALL

81

Block due to

combustion during

start-up

- Check for blockage in

chimney

- Bleed the air from the gas

circuit

ALL

82

Block due to

numerous

combustion control

failures

- Check electrode

- Check outlets

ALL

83

Irregular combustion

(temporary error)

- Check for blockage in

chimney

ALL

84

Flow rate reduced

for (presumed) low

pressure on mains

gas

- Check gas flow rate

Содержание Brava Slim HE 20 R i

Страница 4: ...4 ...

Страница 42: ...42 12 EXPLODED VIEWS Brava Slim HE 20 R i Brava Slim HE 40 R i ...

Страница 43: ...43 Brava Slim HE 20 R e Brava Slim HE 40 R e ...

Страница 44: ...44 Brava Slim HE 20 R i Brava Slim HE 20 R e Brava Slim HE 40 R i Brava Slim HE 40 R e ...

Страница 45: ...45 Brava Slim HE 20 R i Brava Slim HE 20 R e Brava Slim HE 40 R i Brava Slim HE 40 R e ...

Страница 46: ...46 Brava Slim HE 20 R i Brava Slim HE 20 R e Brava Slim HE 40 R i Brava Slim HE 40 R e ...

Страница 55: ...55 ...