2683

1

GB

INDEX

1.

BURNER DESCRIPTION

One stage light oil burner.

1.1 BURNER EQUIPMENT

Flange with insulating gasket . . . .No. 1

Screws and nuts for flange to be fixed to boiler . . No. 4

Screw and nuts for flange . . . . . .No. 1

Flexible oil pipes with nipples . . . . . . . . . . . . . . . . No. 2

Grommet . . . . . . . . . . . . . . . . . . .No. 1

7 pin plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . No. 1

1.

BURNER DESCRIPTION . . . . . . . . . . . . . 1

1.1

Burner equipment . . . . . . . . . . . . . . . . . . 1

2.

TECHNICAL DATA . . . . . . . . . . . . . . . . . 2

2.1

Technical data . . . . . . . . . . . . . . . . . . . . . 2

2.2

Working fields . . . . . . . . . . . . . . . . . . . . . 2

2.3

Overall dimensions . . . . . . . . . . . . . . . . . 3

3.

INSTALLATION . . . . . . . . . . . . . . . . . . . . 3

3.1

Boiler fixing . . . . . . . . . . . . . . . . . . . . . . . 3

3.2

Hydraulic systems . . . . . . . . . . . . . . . . . . 4

3.3

Electrical wiring . . . . . . . . . . . . . . . . . . . . 5

4.

WORKING . . . . . . . . . . . . . . . . . . . . . . . 6

4.1

Combustion adjustment. . . . . . . . . . . . . . 6

4.2

Nozzles recommended . . . . . . . . . . . . . . 6

4.3

Electrodes setting . . . . . . . . . . . . . . . . . . 7

4.4

Air damper adjustment . . . . . . . . . . . . . . 7

4.5

Pump pressure . . . . . . . . . . . . . . . . . . . . 7

4.6

Fuel heating . . . . . . . . . . . . . . . . . . . . . . 7

4.7

Burner start-up cycle . . . . . . . . . . . . . . . . 8

5.

MAINTENANCE . . . . . . . . . . . . . . . . . . . 8

6.

FAULTS / SOLUTIONS . . . . . . . . . . . . . . 9

■

The burner meets protection level of IP 40, EN 60529.

■

Burner with CE marking in conformity with EEC directives: EMC 89/336/EEC, Low Voltage 73/23/EEC,

Machines 98/37/EEC and Efficiency 92/42/EEC.

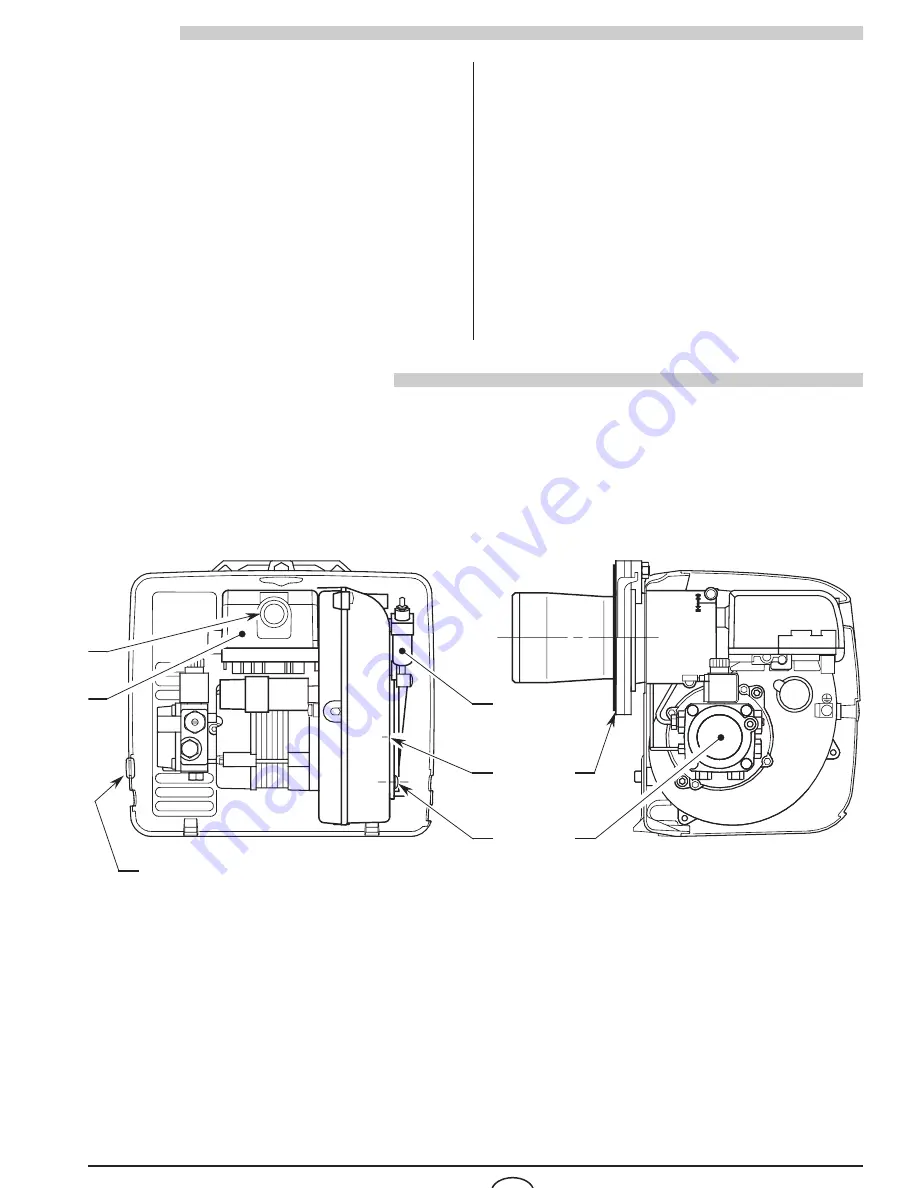

1

– Oil pump

2

– Control-box

3

– Reset button with lock-out lamp

4

– Hydraulic jack with air-damper

5

– Screws fixing air-damper

6

– Flange with insulating gasket

7

– Grommet

Fig. 1

D6272

1

2

3

4

6

5

5

7

Содержание 8099000

Страница 2: ...4...