2

Lubrication and Maintenance

Daily Maintenance

General

During the first few days of operation, before

starting each day, check that all hardware is

tight and tighten all hose clamps. Inspect the

unit for leaks while running.

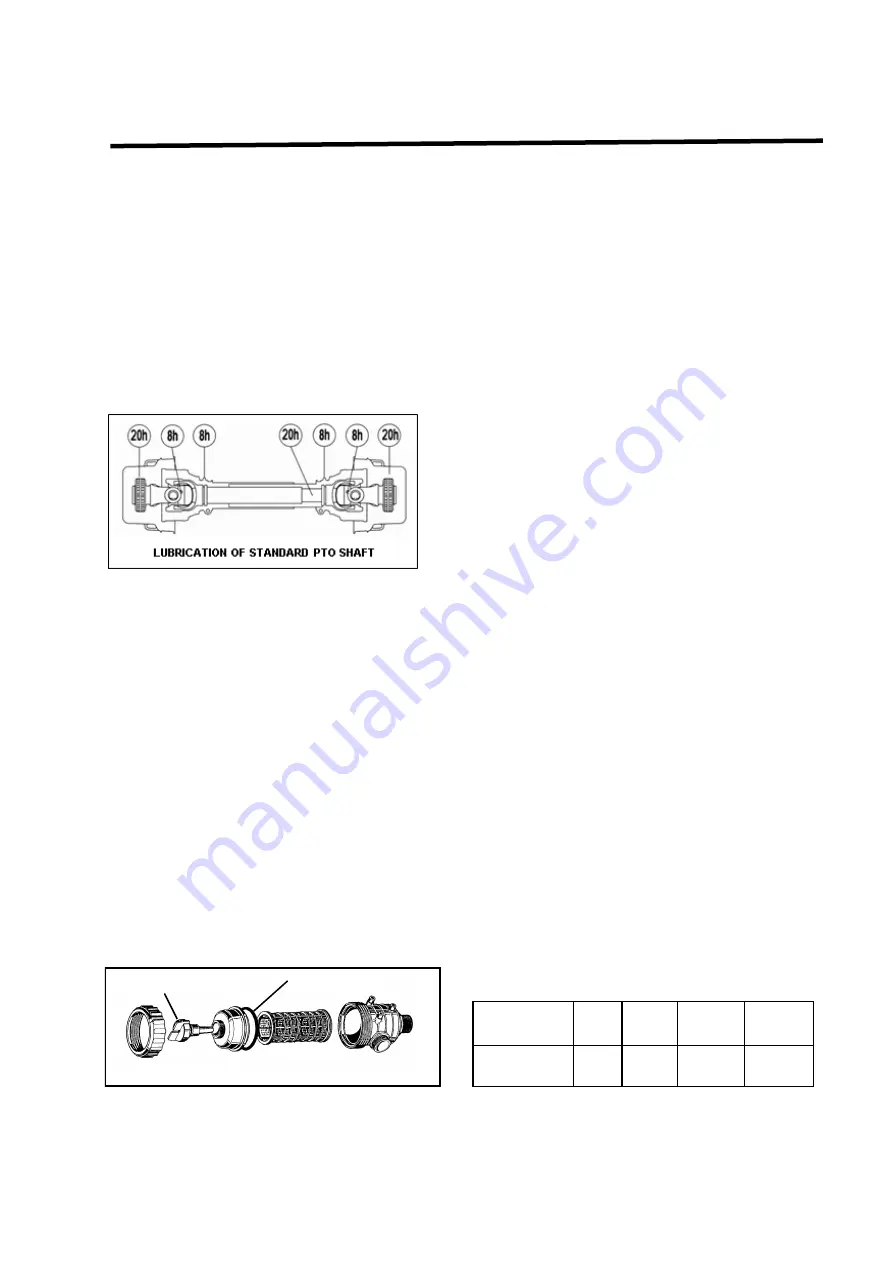

PTO Shaft

Grease the PTO shaft with multi- purpose

grease at the intervals shown below. This is

the amount of lubrication recommended for

normal operation. More frequent inspection

and lubrication may be needed under very

dusty conditions.

Pump

Check the oil level in the viewer daily and if

necessary top up with SAE 20W-40 multigrade

engine oil. The oil must reach the mark on the

side of the oil level viewer.

Filters

Clean all filters as stated below. More frequent

cleaning may be found necessary depending

upon circumstances. The best method for

cleaning filters is to wash them with a soft

bristle brush. Check for any tears or holes and

replace if damaged.

Check and if necessary clean the basket

strainer under the tank lid before each fill.

Always clean the suction filter before each

tank refill and at the end of the day. Close the

stop valve by pushing in and unscrewing the

yellow/red tap, then unscrew the filter cover to

remove the element. Ensure the O-ring is in

good condition when refitting.

Spraying (Bar)

pressure (psi)

2 - 5

29 - 73

5 - 10

73 - 145

10 - 20

145 - 290

20 - 50

290 - 725

Surge air (Bar)

pressure (psi)

2

29

2 - 5

29 - 73

5

– 7

73 - 102

7

102

O-Ring

SUCTION FILTER COMPONENTS

Stop Valve Tap

Tank, Pump and Spray Lines

At the end of each day run clean water through the

pump and lines to purge them of chemicals.

Rinse out the tank to remove powdered material.

Never leave chemicals in the tank that may settle

to the bottom, harden and break into lumps as this

may block the suction filter.

Dispose of unused chemical, chemical mix, rinse

water and chemical containers as recommended

by the chemical manufacturer or appropriate

government authority.

Weekly Maintenance

PTO Shaft (Every 20 Hrs)

Slide the PTO shaft

apart, clean the telescopic tubes with kerosene and

apply multi-purpose grease to the sliding surfaces,

then reassemble.

This is most important in dusty conditions.

Monthly Maintenance

Gearbox.

Check the oil level every 50 hours and if

required top up with SAE 80W-90 gear oil.

The oil should be level with the centre of the input

shaft and can be checked through the filler plug in

the top of the gearbox using a piece of wire as a

dip stick.

Annual Maintenance

Diaphragm Pump.

Drain the oil from the pump

annually, or at the end of each spraying season.

Remove the pump heads, carefully inspect the

diaphragms and replace if necessary. Also check

the inlet and outlet valves, seats and springs for

wear, damage or chemical corrosion and replace

as necessary. Refill with SAE 20W-40 multi-grade

engine oil.

Check the air pressure in the surge chamber at the

end of the pump. The air pressure behind the

chamber’s diaphragm smoothes out the pulsations

in fluid flow and should be set in accordance with

the spraying pressure being used - refer chart

below. Adjust the pressure at the valve fitting on

the chamber using a compressed air hose fitted

with a tire valve connection and a reliable pressure

gauge.