7

ADJUSTMENTS

WEAR SAFETY GLASSES WITH SIDE SHIELDS WHICH CONFORM TO ANSI STANDARD

Z87.1. FAILURE TO WEAR SAFETY GLASSES COULD RESULT IN SEVERE PERSONAL

INJURY. PROTECT YOUR EYES. READ GENERAL SAFETY INSTRUCTIONS IN THE FRONT

OF THIS MANUAL

•

Only trained people should service machine

•

Unless specified, shutoff and lock out all electrical power.

•

Follow all service instructions.

•

Use Correct tools.

•

Never adjust, repair or oil moving machinery

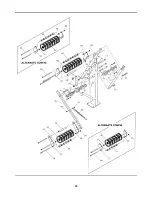

DANCER ARM COMPRESSION SPRING

This adjustment has been factory made and should

not be readjusted. Any additional preloading on this

spring may cause chain or connecting link failure

during operation.

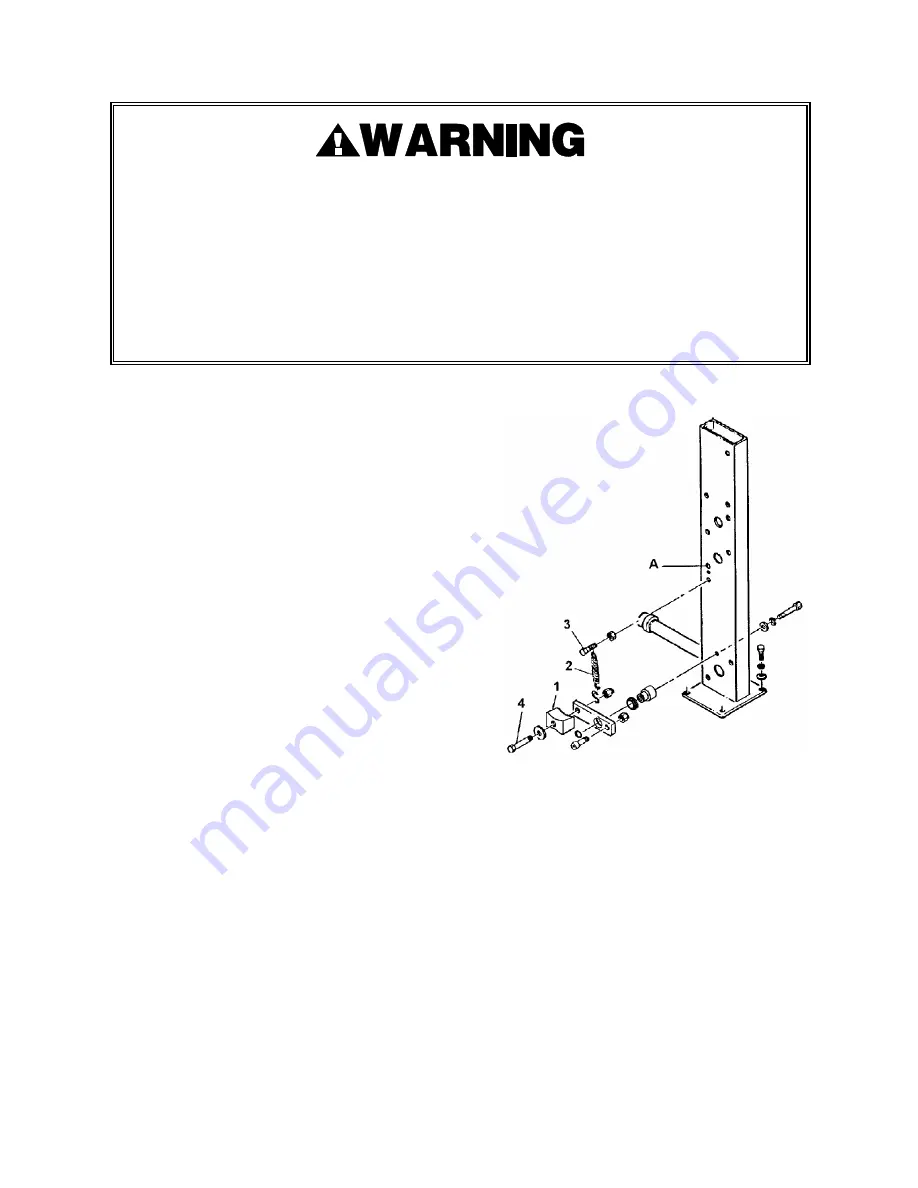

BRAKE BLOCK PRESSURE

Pressure is applied to the brake block (1) by means of

an extension spring (2) connected between the brake

block mounting screw (4) and a 5/16 hex head cap

screw (3) extending from the dispenser post (A) just

beneath the dispenser shaft mounting hole. At this

upper location are two 5/16-24 tapped holes.

Additional spring tension can be gained by removing

the 5/16 hex head screw and moving it to the upper

hole. Make sure the screw extends no more than 3/4"

and it is securely locked to the post with nut

provided.

BRAKE BLOCK ROTATION

The friction surface on the brake block (1) will eventually wear to a point that proper pressure

gained from the extension spring (2) is no longer possible. When that occurs, loosen the brake

block mounting screw (4) and rotate the block 180 degrees. Make sure the mounting screw has

been securely tightened. When both sides of the brake block are fully worn, replace the block.

Содержание 513684

Страница 1: ...PSD 109 STRAP DISPENSER ...

Страница 4: ...4 RIGHT HAND ORIENTATION LEFT HAND ORIENTATION MAJOR COMPONENTS ...

Страница 15: ...15 BLANK ...

Страница 17: ...17 ...

Страница 19: ...19 ...

Страница 21: ...21 ...

Страница 23: ...23 ...

Страница 24: ...SIGNODE 3620 WEST LAKE AVENUE GLENVIEW ILLINOIS 60025 U S A Copyright 2009 Signode 512146 5 2009 ...