Document Number 129-409

RWD45U Controller Installation and Commissioning Guide

October 5, 2009

Page

6 of 13

Siemens Industry, Inc.

Display Explanation, Continued

Symbol

Description

Setting Range

Symbol

Description

Setting Range

PS 2 – Unit X1, X2 and X3 Sensor Type and Sensing Range Definition

Unit

Define unit

°F or °C

ΔX1

Calibration offset for X1

(Ni and Pt sensor only)

-9°F to 9°F

-5 K to 5 K or

X1NI 1000 X1 is Ni 1000

Ω

temperature sensor

Ni 1000

Ω

: -58°F to 302°F

(-50°C to 150°C) (unchangeable)

ΔX2

Calibration offset for X2

(Ni and Pt sensor only)

-9°F to 9°F

-5 K to 5 K or

X2NI 1000 X2 is Ni 1000

Ω

temperature sensor

Ni 1000

Ω

: -58°F to 302°F

(-50°C to 150°C) (unchangeable)

ΔX3

Calibration offset for X3

(Ni and Pt sensor only)

-9°F to 9°F

-5 K to 5 K or

X3NI 1000 X3 is Ni 1000

Ω

temperature sensor

Ni 1000

Ω

: -58°F to 302°F

(-50°C to 150°C) (unchangeable)

X1L

Start point of the X1

(for 0 to 10 Vdc only)

-100 to 2400

X1Pt 1000 X1 is Pt 1000

Ω

temperature sensor

Pt 1000

Ω

: -4°F to 356°F

(-20°C to 180°C) (unchangeable)

X2L

Start point of the X2

(for 0 to 10 Vdc only)

-100 to 2400

X2Pt 1000 X2 is Pt 1000

Ω

temperature sensor

Pt 1000

Ω

: -4°F to 356°F

(-20°C to 180°C) (unchangeable)

X3L

Start point of the X3

(for 0 to 10 Vdc only)

-100 to 2400

X3Pt 1000 X3 is Pt 1000

Ω

temperature sensor

Pt 1000

Ω

: -4°F to 356°F

(-20°C to 180°C) (unchangeable)

X1H

Stop point of the X1

(for 0 to 10 Vdc only)

-100 to 2400

X1 0-10

X1 is 0 to 10 Vdc input

sensor

0 to 10 Vdc: -100 to 2400

X2H

Stop point of the X2

(for 0 to 10 Vdc only)

-100 to 2400

X2 0-10

X2 is 0 to 10 Vdc input

sensor

0 to 10 Vdc: -100 to 2400

X3H

Stop point of the X3

(for 0 to 10 Vdc only)

-100 to 2400

X3 0-10

X3 is 0 to 10 Vdc input

sensor

0 to 10 Vdc: -100 to 2400

X2SP

Remote setpoint

0 to 10 Vdc or

0 to 1000

Ω

X3

If X3 is independent

control

°C, °F, % ----(no unit display),

X1: 0 to 50°C

⇒

Y1: 0 to 10 Vdc **

X2VR

Variable Resistor

0 to 1000

Ω

PS 1 – Application Number Selection:

Standby mode

AVERAGE

Averaging sensor X1 and

X2

REM

Remote setting

WIN/SUM

AnG

Winter/Summer

changeover by analog

input

ALARM

Alarm indication

WIN/SUM

diG

Winter/Summer

changeover by digital

input

FILTER

Filter alarm indication

X2

⇔

X1

Selecting X2 or X1 as the

main sensor

COMP

Setpoint reset function

Act

Active sensor input

** (X1: 32°F to 122°F (0°C to 50°C)

⇒

Y1: 0 to 10 Vdc). The independent Y1 is programmed as a 0 to 10 Vdc

output corresponding to a temperature range of 32°F to 122°F (0°C to 50°C) for sensor input X1 (Ni1000,

Pt1000). When this function is selected there is no economizer or a second independent control loop, and input

X3 is not used.

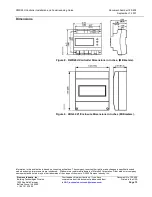

Commissioning

Guide

Commissioning is implemented via push buttons on the controller. The push buttons

have the following functions:

Press

Button to enter the PS page OR edit and save the value when the page

appears with the logo

Press

+

Button for viewing the next page OR to increase the value.

Press

Button for viewing the previous page OR to decrease the value.

Changing a parameter

1. Press the

SEL

λ

button.

:

2. Press the

+

σ

or

–

τ

button to increase or decrease the flashing parameter.

3. Press the

SEL

λ

button to save the value (During PS mode, the values are saved only after exiting the PS mode).

NOTE:

A 9-pin port is provided for optional commissioning via Siemens software tool. See

Software Tool

(Optional Programming).

SEL

+