A wide range of options are

available for integrating WL

circuit breakers in automation

systems. New users will

appreciate the straightforward

and quick start-up options,

while experienced users will

find that the flexible options

meet their requirements.

Communication Options

The PROFIBUS COM15 module

acts as an interface between the

circuit breakers and the information

environment. A joint device master

file (GSD) can be used for integration

in PROFIBUS-DP systems for all

WL circuit breakers. A distinction

between individual breakers and/or

frame ratings cannot and does not

have to be drawn. Of course, with

an identical PROFIBUS-DP profile, the

circuit breaker that is addressed can

be accurately identified (e.g. device

description order number, inspection

date, etc.).

PROFIBUS Communication

Integration into an Automation System

3/1

WL Circuit Breaker

Graphic

3-1

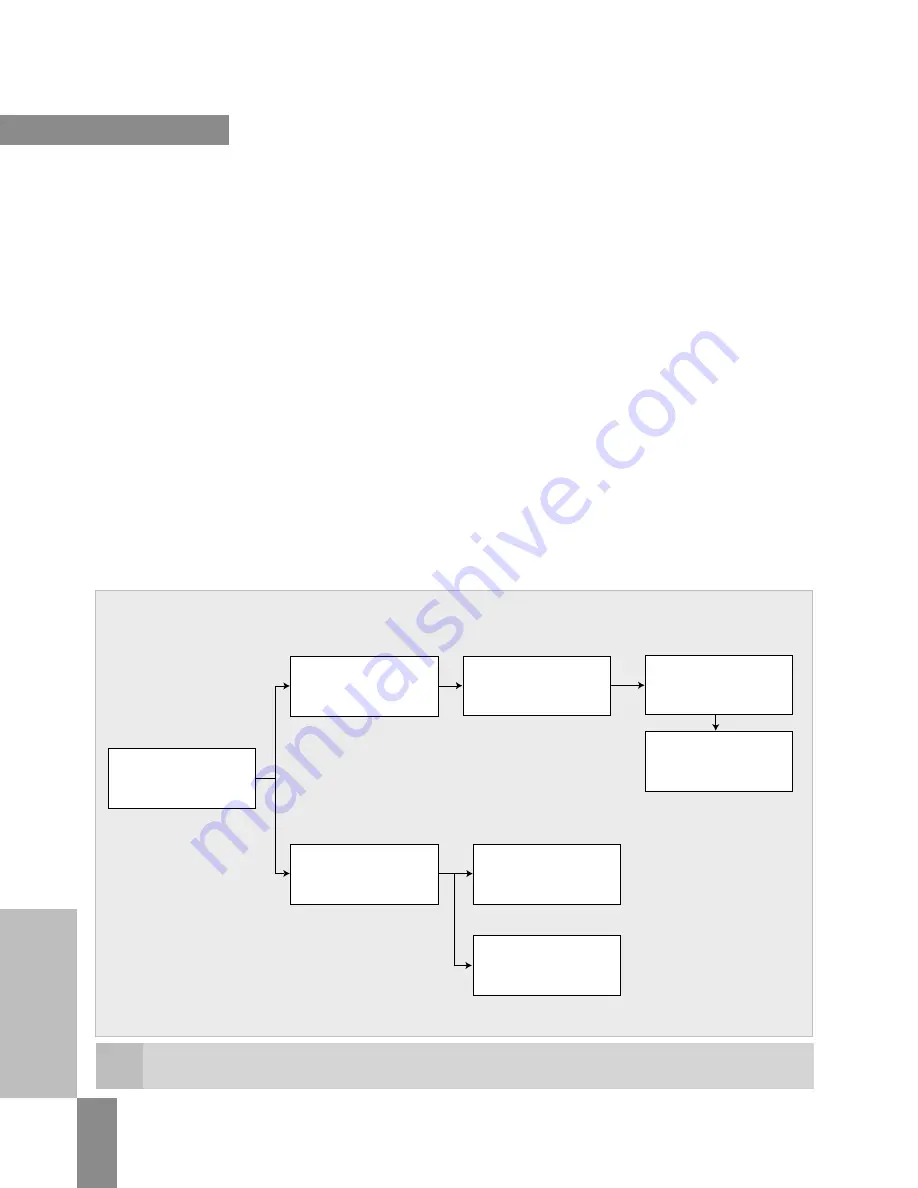

This diagram shows a chart of the different communication options. A class 1 master is the “configuration master,” which transmits either

the settings from the GSD file to the slave during start-up.

Parameterization,

operation, monitoring,

diagnosis via DPV1 C+M

system (e.g. WinCC)

Parameterization,

operation, monitoring,

diagnosis via DPV1 with

an additional PLC

PROFIBUS-DP

communication with

WL circuit breakers

Communication

with the PLC / PC

(class 1 master)

Communication

with the PLC / PC

(class 2 master)

Optional access

via DPV1

Connection as

standard DP slave

Configuration with

GSD file and

master-specific tool

WL PROFIBUS Communication and Electronic Accessories • July 2004