s

Product documentation 1D

3.8.

en

Rev. E, 10/13

page 33/42

4.5

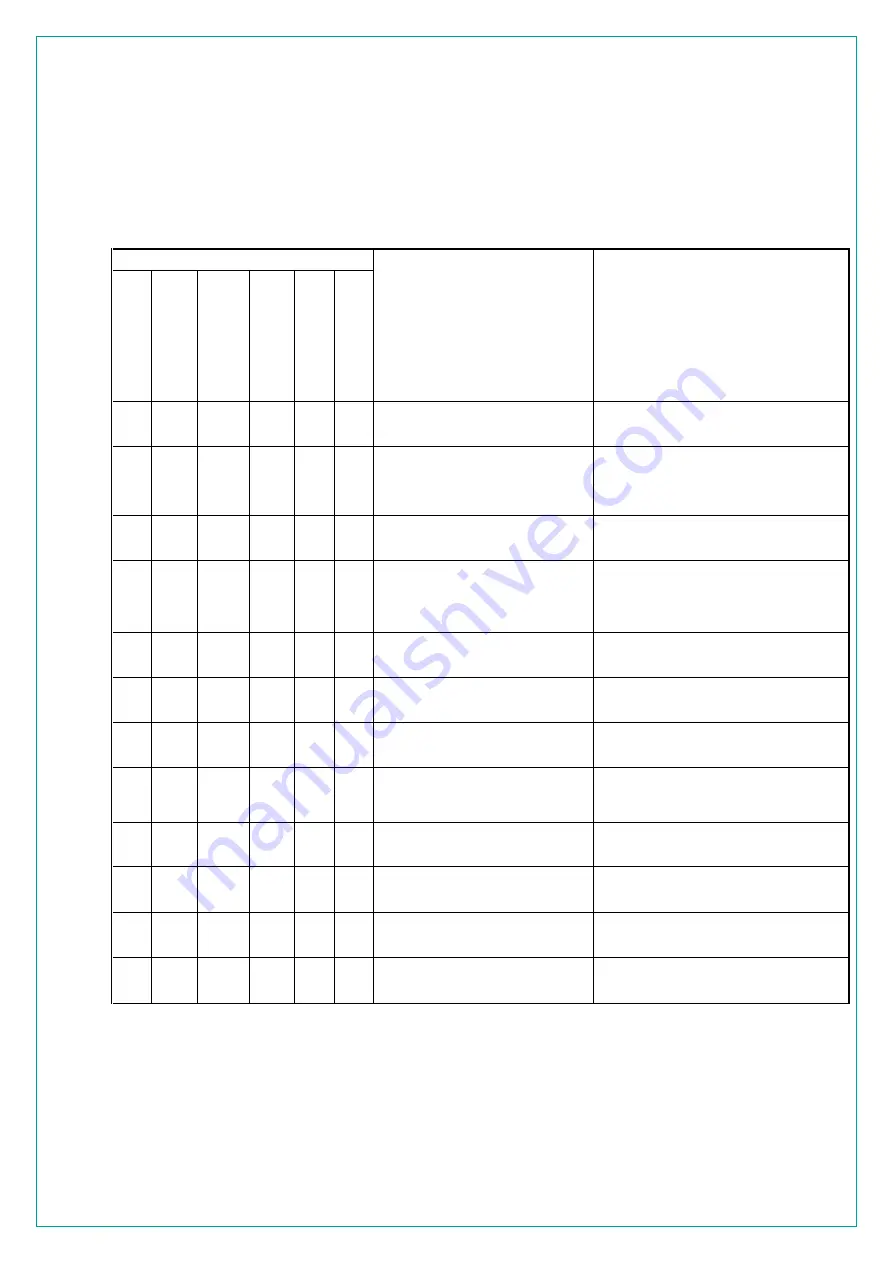

Diagnostics of defects

4.5.1

Mechanical causes

Breakdown

Possible cause

Remedy precaution

Scr

at

chy

no

is

e

Bea

ri

n

g

s a

re

o

ver

h

ea

ted

Ex

ce

ssi

ve

tem

per

at

u

re o

f

g

en

er

at

or

Radi

al

v

ibr

ati

on

Axia

l v

ib

ra

tio

n

Ex

ce

ssi

ve

n

oi

se

•

Contact of rotor or shaft with

solid parts of machine appears

Find and eliminate cause

•

Limited access of air, excessive

amount of dust in winding,

dust in cooler ducts

Perform check of access of air,

pollution of winding, check cooler

•

Polluted or blocked air filter (if

it is equipped)

Filter exchange, if need to clean

•

Cooler function gets worse

(goes for design with water

cooler)

Clean cooler with regards to

operational instructions, check

amount of cooling medium, vent

cooler

•

Unbalance on rotor

Contact producer and require

balancing

•

Unbalance in coupling

Rebalancing

•

Transfer of vibration from

linked machine

Check of linked machine

•

•

Badly fixed generator in

foundation or changes in

foundation

Level machine, check foundation,

and tightening of generator

•

•

Resonance with foundation

Strengthen foundation

•

Lack of lubricant in bearing

Check amount of lubricant in bearing

•

Bearing is overloaded

Check tightening, levelling and

clamping of machine

•

Damaged or badly worn out

bearing

Perform exchange

Tab. 9 Mechanical causes