8

SE80/185T & SE100/185T Ignition Protected thruster assembly

1.0 - 2007

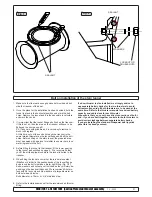

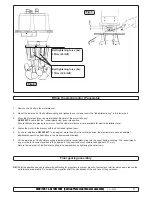

1. Remove the 4 bolts in the motorbracket.

2. Mount the lower part of the flexible coupling and tighten the set screws. Insert the "rubber/plastic ring" in this lower part.

3. Place the motor gently on the motorbracket. Be careful, the motor is heavy!

SE80/185T:

Ensure that the "rubber/plastic ring" goes into position.

Ensure that you are placing the motor so that the cable terminals on it are available for electric installation later.

4. Fasten the motor to the bracket with the 4 bolts and tigthen them.

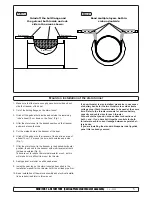

5. If you are installing a

SE100/185T

in an angle of more than 45

o

off a vertical position, the electromotor needs a separate/

additional support. See illustration in the measurements drawings.

6. Lift the lower part of the flexible coupling together with the rubber/plastic ring into the upper flexible coupling. The rubber/plastic

ring must be in its correct position in the upper part, fully inserted but not compressed against it (17 mm).

Secure the lower part of the flexible coupling in its new position by tightening the set-screws.

NB !

Paint the gearhouse and propeller with antifouling for propellers to prevent growth of barnacles or similar which would reduce the

performance dramatically. Do not paint the propeller shaft, the zincanodes or the end face of the gearhouse.

Fitting the electromotor IP assembly

Final gearleg assembly

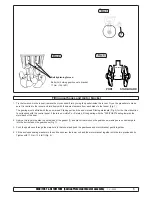

Fig. 2

Bolt tightening force (4x):

33 Nm (24 lb/ft)

Bolt tightening force (2x):

17 Nm (12,4 lb/ft)

Fig. 1