9

Troubleshooting

9.1

Safety

DANGER

Hazard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

b

Immediately shut the machine down if the behavior of the machine cannot be

clearly identified.

b

If a machine fault cannot be definitively determined or safely rectified, immediately

shut the machine down.

b

Secure the machine so that it cannot switch on unintentionally.

NOTE

Additional information on troubleshooting can be found at the responsible SICK subsid‐

iary.

9.2

Status indicator (LED)

Status indicator (LED)

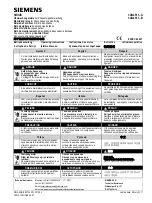

Table 5: Fault indicators and operational statuses

LED

Status

Possible cause

PWR

o

No supply voltage

All LEDs

Ö

All colors

Initialization with LED test

PWR

O

Green

No fault

PWR

Ö

Red (2 Hz)

•

Supply voltage too low temporarily or per‐

manently

•

Internal error

PWR

Ö

Red (1 Hz)

Configuration is invalid

PWR

Ö

Red/green

Error

Additional LEDs flash for accurate diagnosis.

OUT

o

Enabling current paths open

OUT

O

Green

Enabling current paths closed

OUT

Ö

green (1 Hz)

Error in enabling current path

S1

O

Green

Reset pushbutton actuated, N/C contact of the

actuator closed

I1 and I2

Ö

Green, alternate

Input error: discrepancy time expired

I1 and I2

Ö

Green, simultane‐

ous

Input error: cross-circuit, process error

Y1

o

Enabling current paths closed

Y1

O

Green

Enabling current paths open

Y2

o

Output with LOW status

Y2

Ö

Green

Reset required

Y2

O

Green

Reset pushbutton actuated

Complementary information

•

9

TROUBLESHOOTING

26

O P E R A T I N G I N S T R U C T I O N S | ReLy MULT1

8024307/2021-07-30 | SICK

Subject to change without notice