19

8026473/V1-0/2021-01| SICK AG

O P E R A T I N G I N S T R UC TI O N S | MCR

Subject to change without notice

COMMISSIONING

5

5.2.1

Application settings

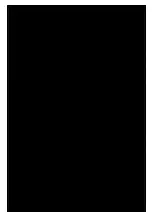

The following basic settings can be configured in the Application tab of the

Settings

page.

●

Device data

: Login data to the respective cloud provider.

●

Parameters

: Switching between the “Aggregation” and “Scan” operating modes.

Aggregation is currently supported only by medAspis.

●

Pre-select the FMD modes that the operator can choose from on his screen.

●

Enable/disable “NoReads” feature to indicate possible faulty read processes.

Fig. 7: Application settings

Содержание MCR

Страница 1: ...MMMI MMMOPERATING INSTRUCTIONS OPE RATI NG INSTR UCTIO NS MCR Multi Code Reader ...

Страница 23: ......