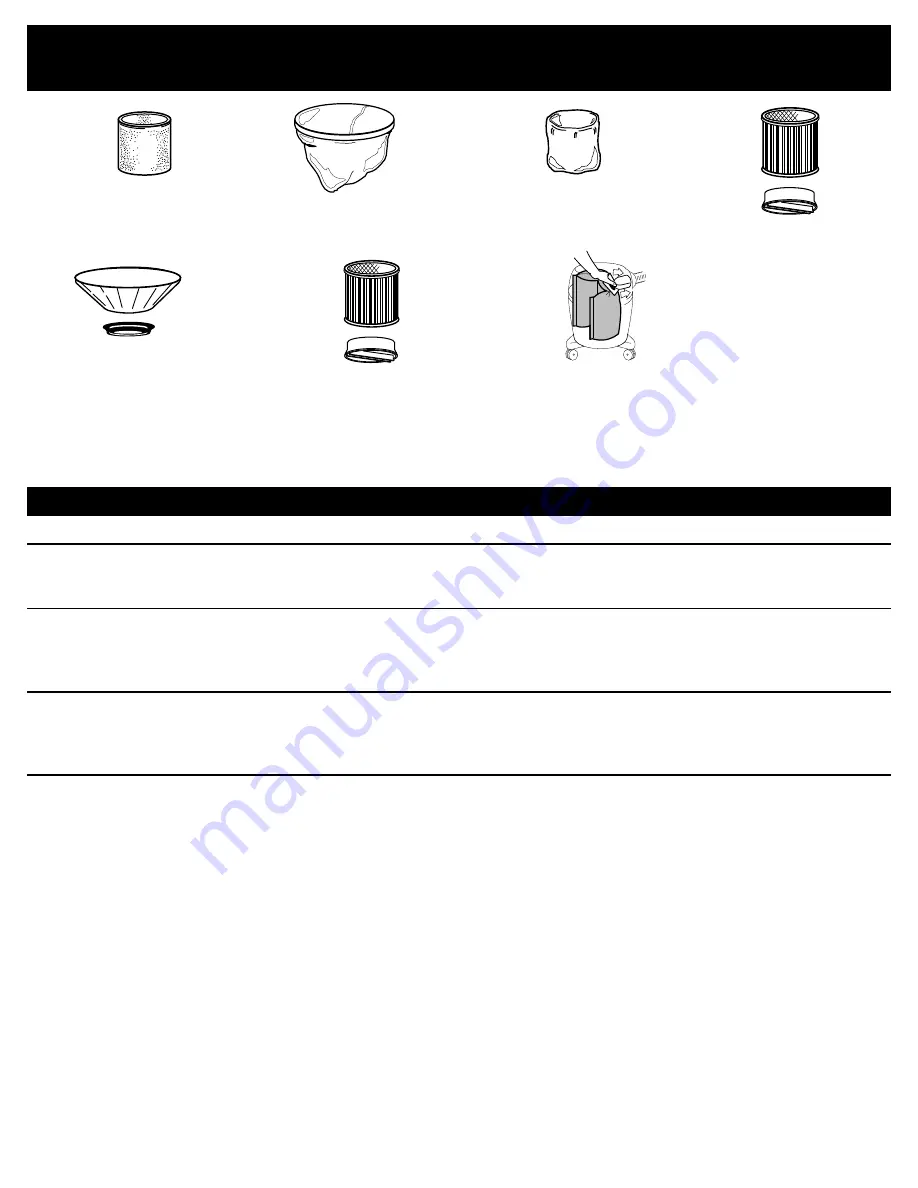

Foam Sleeve

Rinse with water, dry and reinstall.

SHOP-VAC

®

VACUUM FILTER

CLEANING REFERENCE

Reusable Disc Filter

Rinse with water, dry and reinstall; do not

machine wash.

Cartridge Filter &

Ultra Web

®

Cartridge Filters

From inside of filter, rinse with water, dry com-

pletely and reinstall.

Super Performance Filter

Dispose of after filter develops rips or tears.

Full Polyester Filter

Brush off dirt and reinstall; if filter gets wet,

rinse with water, dry and reinstall.

All Collection Bags

Dispose of bag when full.

Cleanstream

®

Cartridge Filters

Clean installed filter by simply tapping or

shaking the vacuum unit. To restore optimum

airflow, remove filter, tap end cap against

a hard surface to loosen debris. Additional

debris can be removed by rinsing outside

surface of filter with running water. Avoid

dampening inside of filter. Completely air dry

filter after washing.

Troubleshooting Chart

Parts/accessories missing

1. Packed in tank

1. Check in tank

Vacuum cleaner will not start

1. No power at receptacle

1. Check for power

2. Defective switch

2. Replace switch

3. Defective motor

3. Replace motor

Dust discharging from exhaust

1. Filter not installed/not installed properly

1. Properly install filter

2. Filter damaged

2. Replace filter

3. Filter clogged or dust is too fine

3. Use more efficient filter

4. Filter not functional

4. Clean and replace filter

Loss of suction

1. Loose hose connection

1. Tighten hose connection

2. Filter clogged

2. Clean or replace filter

3. Full tank

3. Empty tank

4. Hole in hose

4. Replace hose

Static shock

1. Dry environment

1. Add moisture to air (if practical, use a console

or installed humidifier).

2. Relative humidity of air is low

2. This situation is temporary and does not

affect the use of the vacuum cleaner.

Symptom Possible Cause(s) Corrective Action