18

R - 2 2 A T

R-23AM

R - 2 4 A T

CONTROL PANEL ASSEMBLY FOR R-23AM

OUTLINE OF CONTROL PANEL

The control section consists of the following units as

shown in the control panel circuit.

(1) Control Unit

(2) Switch Unit

(3) Encoder Unit

The principal functions of these units and the signals commu-

nicated among them are explained below.

1. Control Unit

Signal of switch touch and oven function control are all

processed by one microcomputer.

1) Power Supply Circuit

This circuit changes output voltage at the secondary

side of the low voltage (T1) transformer to volatges

required at each part by full wave rectifying circuit,

constant voltage circuit, etc..

2) ACL Circuit

This is an Auto-clear Circuit, i.e., a reset circuit, which

enables IC1 to be activated from initial state.

3) Power Synchronizing Signal Generating Circuit

This is a circuit for generating power synchronizing

signal by virtue of the secondary side output of trans-

former T1.

This signal is used for a basic frequency to time

processing and so on.

4) Clock Circuit

This is a circuit for controlling clock frequency required

for operating IC1.

5) IC1 (Main Processor)

This is a one-chip microcomputer, responsible for

controlling the entire control unit.

6) Display Circuit

This is a circuit for driving display tubes by IC1 output.

7) Switch Input Circuit

This is a circuit for transmitting switch input information

to IC1.

8) Sound-body Driving Circuit

This is a circuit for driving sound body by IC1 output.

9) Relay Driving Circuit

This is a circuit for driving output relay by IC1 output.

10) Stop Switch Circuit

This is a circuit for driving IC1 to detect door opening/

closing.

11) Exhaust Air Temperature Detecting Circuit

This is a circuit for transmitting output change of

thermistor (Oven thermistor (1)) to IC1.

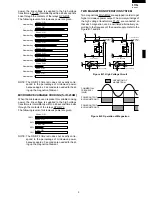

12) High Voltage Monitoring Circuit.

This circuit detects problems in the magnetron / high

voltage circuit by sensing a variation in the current

flowing through the primary winding of the high voltage

transformer. During heating, the primary current of the

high voltage transformers also flows through the pri-

mary winding of the current transformers CT1 and

CT2. This causes a current to be induced in the

secondary windings of CT1/CT2 and results in an AC

voltage which is determined by R30/R31. This AC

voltage is then half wave rectified by D30/D31 and

smoothed (filtered) by C30/C31. This AC voltage is the

input to the AN3 and AN4 ports of IC1, which deter-

mines if there is a magnetron / high voltage problem.

Figure T-1. High Voltage Monitoring Circuit For R-23AM

13) Magnetron Temperature Detecting Circuit.

This is a circuit for transmitting output change of

thermistor (Magnetron thermistor) to IC1.

14) Oven Cavity Temperature Detecting Circuit.

This is a circuit for transmitting output change of

thermistor (Oven thermistor (2)) to IC1.

2. Switch Unit

The switch unit is composed of a matrix circuit in which

when a switch it touched, one of signals P43 - P45

generated by the LSI, is passed through the switch and

returned to the LSI as one of signals P50 - P51.

3. Encoder

The encoder converts the signal generated by LSI into

the pulse signal, and the pulse signal is returned to the

LSI.

HIGH VOLTAGE TRANSFORMER

HIGH VOLTAGE CIRCUIT

MAIN BODY SIDE

T/C SIDE

CT1 or CT2

RY2 or RY3

R30 or

R31

R34 or

R35

D30 or

D31

R32 or

R33

Vc

C30 or C31

IC1

AN3 or

AN4 PORT

D32 or

D33

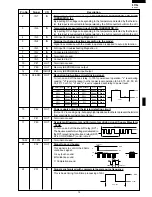

DESCRIPTION OF LSI FOR R-24AT / R-22AT

LSI(IZA646DR)

The I/O signal of the LSI(IZA646DR) is detailed in the following table.

Pin No.

Signal

I/O

Description

1

VREF

IN

Reference voltage input terminal.

A reference voltage applied to the A/D converter in the LSI. Connected to GND.(0V)