5. Flash Eeprom Service Writing/Checking

Procedures

The procedures are for writing into the FLASH-EEPROM in the ZR-

3000/3500X. Servicing for the ZR-3000/3500X is performed in the

following cases:

•

When the MAIN PWB unit is replaced.

•

When the MAIN ROM PWB is replaced.

•

When the FLASH-EEPROM version is updated.

Introduction

Writing into the FLASH-EEPROM of the ZR-3000/3500X is performed

in the following procedures.

•

Install the patch transfer program of the FLASH-EEPROM for IBM

PC.

•

Connect the unit with the IBM PC and write.

5-1. Installing the patch transfer program of the

FLASH-EEPROM for IBM PC

1) Necessary devices

•

IBM PC (compatible machine): MS- Windows 95 installed in the

hard disk

•

Floppy disk 1 (

*

2): Check the label

ZR-3000/3500X ROM V1.0 or later

FLASH-EEPROM writing software

for MS- Windows 95

Ver F .F mm/dd/yy

Disk content:

\setup\*.*

: Writing tool

\Z-lite(x).Vxx(

*

3): Data

*

1: Trademark Microsoft

*

2: Supplied by SHARP. In the future, it may be supplied through

the communication network instead of by a floppy disk.

*

3: "xx" shows the version number.

2) Operating procedure

1. Turn on the power of the IBM-PC (compatible machine) to start

the MS- Windows.

2. Set the disk to IBM PC (compatible machine).

3. Start the explorer.

4. Make a working directory.

5. Use the explorer to execute\setup\setup.exe.

6. Follow the instruction of the install program.

[Note] DLL files are copied into the directory of \Windows\Systems.

5-2. Rewrite procedure of 1 Mbit FLASH-EEPROM in

the ZR-3000/3500X (ROM version 1.0 or later)

1) Necessary devices

•

IBM-PC (Compatible machine): MS- Windows 95 installed in the

hard disk.

•

AC adapter (EA-23E) for the ZR-3000/3500X: 1 unit

•

Floppy Disk: 1 (

*

2): Check the label.

•

RS-232C cross cable (Since the hardware flow is required, RTS

and CTS must be connected.)

•

RS-232C level convertor [CE-137T]

ZR-3000/3500X ROM V1.0 or later

FLASH-EEPROM writing software

for MS- Windows 95

Ver F .F mm/dd/yy

Disk content:

\setup\*.*

: Writing tool

\Z-lite(x).Vxx(

*

3): Data

*

1: Trademark Microsoft

*

2: Supplied by SHARP. In the future, it may be supplied through

the communication network instead of by a floppy disk.

*

3: "xx" shows the version number.

2) Operating procedure

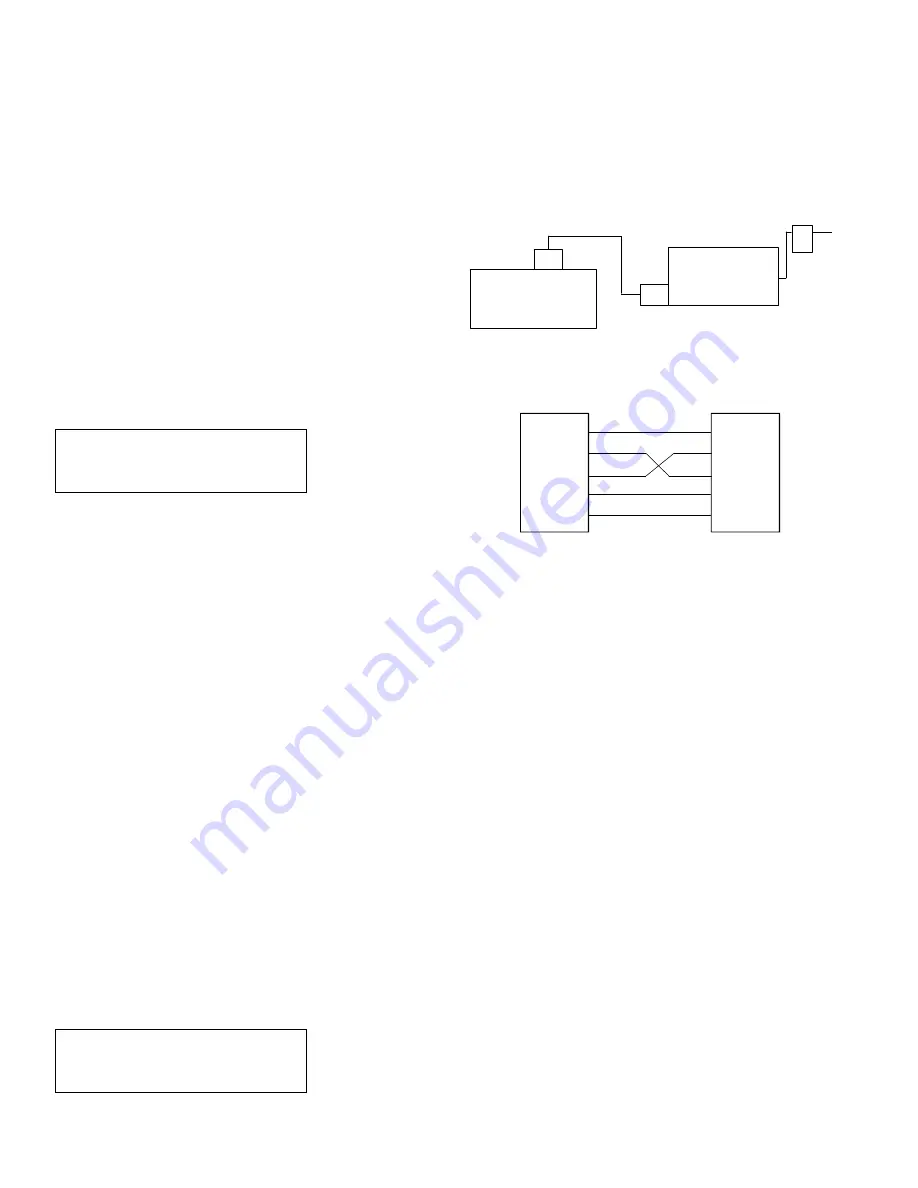

1. Connect the devices as shown below:

< Wiring diagram>

2. Turn on the power of the IBM-PC (compatible machine) to start

the MS- WINDOWS 95.

3. Start the explorer and start patch.exe.

<Operation on the unit side>

4. Set to the DIAG mode, and select (43 ERASE 1M FLASH).

The patch is erased.

5. Set to the DIAG mode, and select (47 UPDATE 1M FLASH).

The display shows "*****UPDATE 1MFLASH*****."

<Patch transfer program operation>

6. Use Browse button to select the patch file.

7. Select the COM PORT.

8. Push the send button to send the patch file.

Causes of errors on the unit side are as follows:

(1) SIO ERROR!!:

The communication conditions are

not proper. Time-out (About 5 min).

Repeat the procedures again.

(2) ROM VER ERROR !!:

The ROM version of

ZR-3000/

3500X does not correspond to the

patch data.

(3) PATCH VER ERROR!!:

The PATCH version of ZR-3000/

3500X is later than or the same as

the target patch data.

(4) LOW BATTERY!!:

When ZR-3000/3500X is in low bat-

tery.

(5) ERROR !!:

The other errors than the above.

On the unit side, the "X" bar extends along with the sound, and

the process content is shown on the bar.

READ:

Reading of patch data

RS-232C Cross cable

IBM-PC

(compatible machine)

CE-137T

AC-adaptor

EA-23E

ZR-3000/3500X

DTR

RD

SD

SG

RI

DTR

RD

SD

SG

RI

4

2

3

5

9

21

3

2

7

22

CE-137T

DSUB-9Pin

PC

DSUB-25Pin

– 40 –