PAGE 6

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

ACTION

JACK WILL NOT LIFT TO FULL

HEIGHT

LOW OIL LEVEL

CHECK OIL LEVEL AND REFILL IF

NECESSARY

JACK WILL NOT HOLD LOAD

RELEASE VALVE NOT CLOSING

OIL CONTAMINATED

PUMP VALVES NOT SEALING

CYLINDER RAM BINDING

CONTACT CUSTOMER SERVICE

LIFT ARM WILL NOT LOWER

CYLINDER RAM BINDING

PARTS WORN

INTERNAL DAMAGE

BROKEN RETURN SPRING

LIFT ARM LINKAGE BENT OR

BINDING

CONTACT CUSTOMER SERVICE

JACK FEELS SPONGY WHEN

LIFTING

SEE AIR PURGE SECTION

PURGE TRAPPED AIR

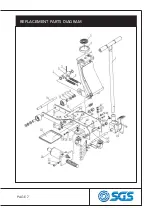

ITEM

DESCRIPTION

QTY

1

SADDLE COVER

1

2

SADDLE

1

3

LIFTING ARM

1

4

UPPER HANDLE

1

5

COTTER PIN 4X50

1

6

CONNECTING BLOCK

1

7

WASHER

2

8

RETURN SPRING

2

9

NUT 18

2

10

SPRING PAD 18

2

11

FLAT PAD 18

2

12

WHEEL FORK SLEEVE

2

13

FRONT WHEEL FORK

2

14

FRONT WHEEL PIN

1

15

SUPPORT SHAFT

1

16

RIGHT PLATE

1

17

LEFT PLATE

1

18

WASHER 20

2

19

NUT 20

2

20

WASHER 14

2

21

NUT 14

2

22

DISK TOOLS

1

23

SCREW 8X16

2

REPLACEMENT PARTS LIST

ITEM

DESCRIPTION

QTY

24

SPRING PAD 8

2

25

SHAFT PIN

1

26

POWER UNIT

1

27

SPRING PAD 12

4

28

SCREW 12X25

2

29

BOLT 6X20

1

30

PAD 10

1

31

PUSHING PLATE

1

32

VALVE

1

33

FLAT PAD 6

1

34

SPRING PAD 6

1

35

NUT 6

1

36

SHAFT PIN

2

37

NUT 12

2

38

FLAT PAD 12

2

39

BUTTERFLY NUT 8

1

40

FLAT PAD 16

2

41

NUT 16

2

42

HANDLE SOCKET PIN

1

43

BACK WHEEL

2

44

SHAFT

1

45

HANDLE SOCKET PIN

1

WWW.SGS-ENGINEERING.COM

Содержание TJ2PRO

Страница 7: ...PAGE 7 REPLACEMENT PARTS DIAGRAM...