PAGE 3

RAISING A VEHICLE

1. Make sure the jack and vehicle are on a hard level surface.

2. Always set the vehicle handbrake and chock the wheels.

3. Consult the vehicle owner’s manual to ascertain the location of

jacking points and position the jack beneath the lift point.

4. Turn the handle counter clockwise to the closed position.

5. To raise the vehicle pump the handle up and down. Do not over

extend the jack past the maximum height.

6. Place jack stands beneath the vehicle at locations recommended

by the vehicle manufacturer. Do not work under the vehicle

without the use of jack stands. Jacks are not designed to maintain

heavy loads for long periods of time. Do not attempt to place jack

stands simultaneously under both ends of a vehicle or along one

side of a vehicle.

7. Turn the handle slowly clockwise to lower the vehicle onto the jack

stands.

LOWERING A VEHICLE

1. Turn the handle counter clockwise to close the release valve.

2. Pump the handle to lift the vehicle off the jack stands.

3. Remove the jack stands. Do not get under the vehicle while the

vehicle is being lowered.

4. Turn the handle slowly clockwise to lower the vehicle onto the

ground.

Содержание TJ2PRO

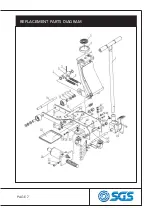

Страница 7: ...PAGE 7 REPLACEMENT PARTS DIAGRAM...