PAGE 5

CHECK THE OIL LEVEL

1. Turn the handle clockwise to allow the ram to fully retract. It may

be necessary to apply force to the saddle to lower the ram.

2. Remove the inspection plate.

3. With the jack in the level position remove the oil fill plug. The oil

should be level with the bottom of the fill hole. If not, top up but

do not overfill. Always fill with new, clean hydraulic jack oil.

4. Replace fill plug and inspection plate.

5. Check jack operation.

6. Purge air from the system as required.

SYSTEM AIR PURGE

1. Fully lower the saddle.

2. Turn the handle clockwise one full turn to open.

3. Locate and remove the oil filler plug.

4. Pump the handle eight full strokes to release pressurised air which

may be trapped in the reservoir.

5. Re-install oil filler plug

6. Turn handle counter clockwise one full turn.

FACTORY SERVICE

If this hydraulic jack if found to be damaged in any way, worn or

operating abnormally it should be removed from service until

inspected by an authorised repair centre.

Owner/operators should be aware that the repair of this jack requires

specialised equipment and knowledge. Only factory authorised parts,

labels and decals shall be used on this equipment. An annual

inspection of this jack by an authorised repair centre is recommended

to ensure the jack maintains an optimum operating condition.

Содержание TJ2PRO

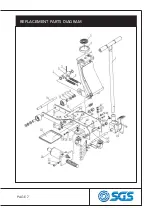

Страница 7: ...PAGE 7 REPLACEMENT PARTS DIAGRAM...