M

–

Basic

Maintenance

M

‐

2

Pool

Water

Chemistry

.

Incorrect

pool

water

chemistry

(improper

pH

level

or

high

concentration

of

chlorine,

sea

salt

or

other

corrosive

additives

etc.)

can

result

in

equipment

premature

wear

or

malfunction

(let

alone

poor

air

quality

in

the

pool

and

potential

health

issues)

and

will

void

the

equipment

warranty.

Refer

to

pool

water

quality

standards;

contact

factory

as

needed.

Routine

Maintenance

Program

Creating

facility

‐

specific

routine

maintenance

program

and

following

it

is

vital

to

equipment

longevity

and

efficient

operation.

The

suggested

general

maintenance

operations

and

their

frequency/intervals,

listed

in

the

table

M

‐

1

below,

can

be

used

to

create

such

a

program.

For

more

detailed

maintenance

recommendations

related

to

specific

components,

refer

to

the

respective

component

manufacturer’s

manual.

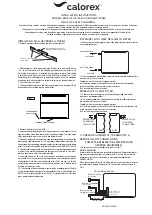

Table

M.1.

Recommended

Maintenance

Tasks

and

Intervals

Interval

Maintenance

Task

Weekly

Observe

the

equipment

for

any

changes

in

running

conditions

and

unusual

noise

Quarterly

Clean

or

replace

air

filters

if

clogged

or

dirty

Verify

that

all

set

‐

points

are

correctly

programmed

as

specified

by

the

facility

operator

Semi

‐

Annually

Inspect

and

clean

the

drain

pan(s)

Tighten

electrical

connections,

if

required

Check

and

tighten,

if

required,

pool

water

hose

clamps

and

sensor

mounts

Inspect

all

airside

coils

(outdoor

condenser,

fluid

cooler,

dehumidifier

coils

–

evaporator,

etc.)

for

dirt,

cobweb

build

‐

up,

etc.;

clean

as

needed

Check

that

the

P

‐

trap

is

primed

(filled

with

water).

It

is

good

practice

to

pour

some

water

into

the

drain

pan

to

ensure

that

the

P

‐

trap

is

primed

and

operational

Check

the

outdoor

air

louvres

and

dampers

for

accumulation

of

dust

and

clean

as

required

Inspect

the

equipment’s

cabinet

for

corrosion.

If

any

damage

is

found,

clean

and

repaint

the

affected

surface

with

a

rust

‐

resistant

primer

Annually

Clean

the

fan

wheel(s)

Check

dampers

operation

(linkage/actuator

is

not

loose,

damper

opens/closes

properly

etc.)

Inspect

electrical

components,

wiring

and

insulation

Rotate

the

fan

wheel(s)

and

check

for

obstructions

and

rubbing

Check

gasket

condition

on

all

doors

to

ensure

an

airtight

seal

Check

bolts

on

compressors,

motor

mounts,

dehumidifier

bases

and

coils

and

tighten

if

required

Verify

that

the

airflow

around

the

remote

condenser

or

dry

cooler

is

unobstructed

Содержание CLASSIC NE-002

Страница 3: ...B Table of Content B 2 This page is left blank...

Страница 10: ...C General Information OMM C S SL 01 C 7 February 2020 Pic C 4 B...

Страница 17: ...D Layout and Components D 6 This page is left blank...

Страница 21: ...E Sequence of Operation E 4 This page is left blank...

Страница 25: ...F Interface and Communication F 4 This page is left blank...