www.sentera.eu

MIW-RTVS1-EN-000 - 03 / 11 / 2020

11 - 12

TRANSFORMER FAN SPEED CONTROLLER WITH

MODBUS RTU COMMUNICATION

RTVS1

Explanation of specific Modbus registers

The unit has factory pre-set parameters written in Modbus map. It can function

without any other settings. However, there are some special registers you may need

to set depending on you combination of products. These are listed in

Table 2

below.

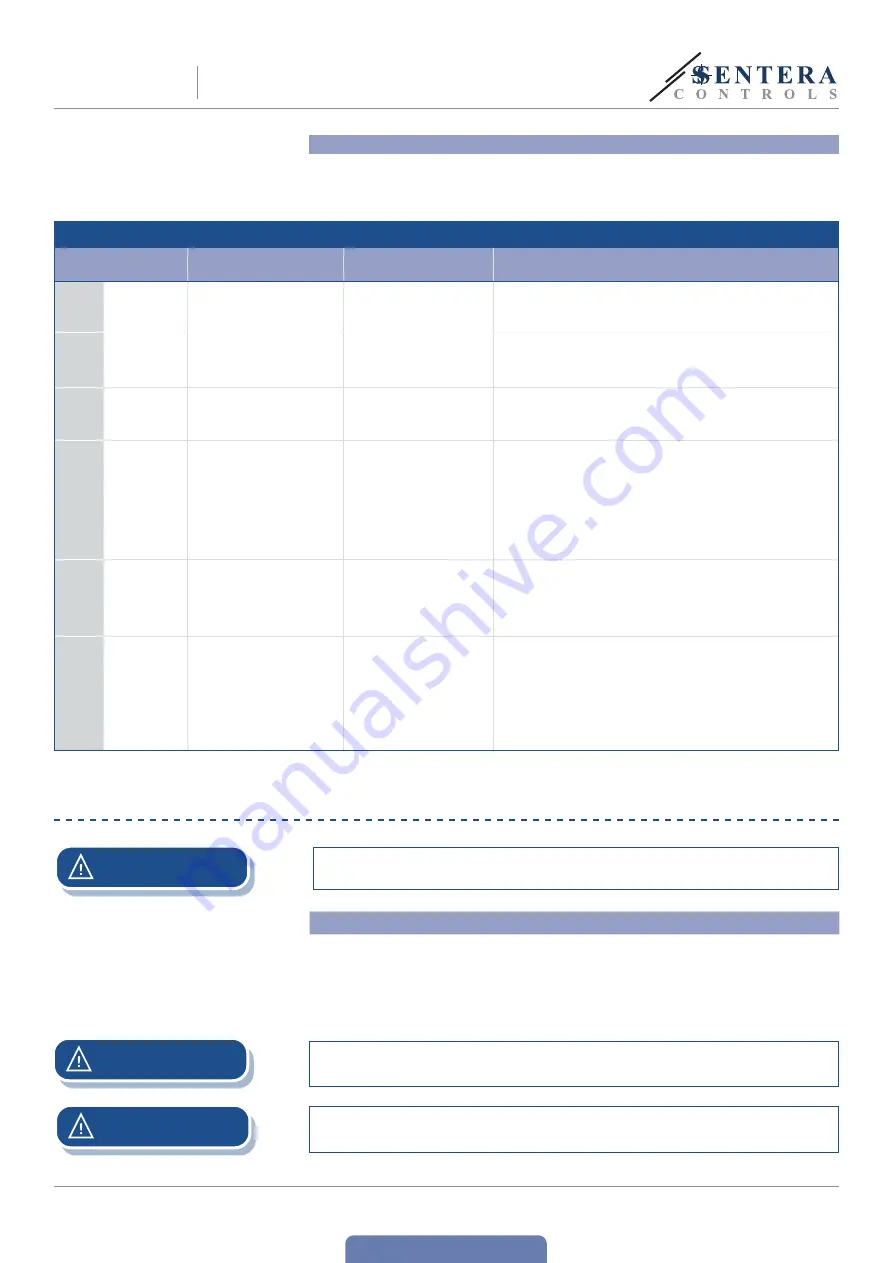

Table 2 Voltage steps

Modbus holding

registers

Description

Values

Remark

11

Control Set

Automatic control – takes value

from sensor. Manual Control –

takes value from register 12

Auto Forward mode;

Manual mode;

Auto Reverse mode

It is possible to change the control of the article only when the switching

of the current command has finished.

13

Output Update

Interval

Time delay to update the

output in automatic mode

5 s—600 s

If the value of the sensor connected is changing too fast this is the

register that provides control of the time between two consecutive

switching.

16

Hysteresis delta

The difference between

the upwards switching and

downwards switching step

percentage

2—10 %

This value is subtracted from the threshold when the article is switching

from high to low input value. Hysteresis value is 2 – 10%, it means for

threshold 20%, the “threshold – hysteresis” = 18% for Δ = 2%.

17

Communication

Lost Output

State

Set output when Modbus

communication is lost

OFF;

Last step selected

Set to 0 = OFF, when there is Modbus Timeout set, when the device

encounters Timeout - RTVS1 enters STOP mode, output is

0. If the remote sensor is lost – device enters state 0 = OFF. Both

communications lost, article goes to OFF.

When set to 1 = Last step selected, on Modbus Timeout occurrence and

sensor is connected – article continues to operate in regarding of the

input from the sensor, if sensor is lost – the article stays on the last

step selected. If both communications are lost, device stays on the last

step selected.

In Auto modes, if there is no communication to the control/monitoring

station, the article continues to operate autonomously while the sensor

is connected.

18

Sensor output

register value

number

Select which sensor output will

be used as input to the device

Digital potentiometer;

Temperature;

Relative Humidity;

CO

2

/CO

2

eq;

CO/TVOC;

NO

2

Sensor output register value number, define which sensor value will be

taken for control of the device switching. The restrictions that apply

are for Sentera Sensors only, and the SPV device. When SPV device is

connected this value becomes automatically 1 and cannot be changed

until other sensor is connected.

21—25

Input value

step 1—5

Input value to switch to output

steps 1—5

Switches to output step X at

X % input value and steps

down to output previous step

at X % - Hysteresis delta

(HR16) set

Input Value Step X – the steps will be activated over these thresholds.

If register value is 0 – this step will be skipped as a holding step, but

it will be used as intermediate step if needed to switch to upper/lower

step. Minimum difference between steps thresholds is 11%, that way any

overlapping of the switching and the hysteresis is avoided.

VERIFICATION OF INSTALLATION

Use only tools and equipment with non-conducting handles when working on

electrical devices.

ATTENTION

Safe operation depends on proper installation. Before start up, ensure the following:

■

The mains supply is connected correctly.

■

Protection is provided against electrical shock.

■

The cables are the appropriate size and fuse-protected.

■

There is sufficient air flow around the unit.

ATTENTION

The unit is supplied with electrical energy at voltages high enough to inflict personal

injury or threat to health. Take the relevant safety measures.

ATTENTION

Disconnect and confirm that there is no live current flowing to the unit before servicing.