18

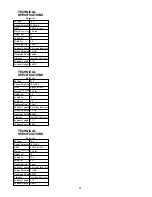

Battery will not charge

Defective battery

See pg #15 for battery error code description

Troubleshooting

Tool will not start or runs slowly

Battery is discharged or defective

Trigger switch is defective

Motor is defective

Replace with charged battery pack

Replace or return to Senco authorized

service center for repair

Tool will not fully drive fastener

Bit is worn

Power capabilities of the tool have been

exceeded

Tool is in reverse

Incorrect bit installed

Depth of drive not set properly

Replace bit

Discontinue use in that application

Switch tool to forward

Ensure correct bit type and length are installed

See pg. #12 for proper adjustment

Tool does not advance fastener

Screw length is improperly set

Return spring is weak

Defective collation material

Defective slide body

Screw strip is jammed in guide track

See pg. #11 for proper adjustment

Replace or return to authorized service center for repair

Use Senco branded fasteners for optimum performance

Replace or return to Senco authorized service center for repair.

Ensure strip slides free in guide track

Screws "kick-out" or miss-drive during use

Screw length improperly set

Incorrect bit installed

Defective or damaged feed system

See pg. #11 for proper adjustment

Ensure correct bit type and length are installed

Return to Senco or Authorized service center for repair

Bit will not install

Bit not properly inserted into drive shaft

Clutch teeth not aligned

Not a Senco bit

See pg. #13 for proper installation

Pulse trigger while holding back release button

Use only the appropriate Senco bit

Bit will not release

Not a Senco bit

Clutch teeth not aligned

Use only the appropriate Senco bit

Pulse trigger while holding back release button

Tool slid forward during drive

Tool is misaligned

Bit is worn or broken

Nosepiece is worn or damaged

If wood nosepiece is used, replace sandpaper pad

Hold tool firmly while driving

Return to Senco or Authorized service center for

repair

Replace bit

Replace or return to Senco authorized service center

for repair

Fastener Jams

Screw length improperly set

Defective collation material

Nosepiece damaged or bent

Screw partially driven into collation material

then feed system released

See pg. #11 for proper adjustment

Use Senco branded fasteners for optimum performance

Replace or return to Senco authorized service center

Remove jammed screw with fingers or pliers and resume

use.

"Slide Mechanism ""sticks"

or returns slowly"

Debris build-up in mechanism

Weak return spring

Bit sticking in collation material

Clean mechanism

Replace or return to Senco authorized service

center for repair

Use Senco branded fasteners for optimum

performance

Always attempt to store screws in cool dry

place before use. Overheated collation can get

soft and cause a delay in feed system return.

Tool Overheats

Drive application requires too much torque Discontinue use in that application

Pushing force becomes excessive

Slide body is worn

CAM screw is loose or damaged

Debris build-up in mechanism

Replace or return to Senco authorized

service center for repair

Tighten or replace CAM screw

Clean mechanism

Bit slips off screw or screw is driven at an

angle

Problem or Symptom

Probable Cause

Corrective Action