Smart Positioner

SP740 Series

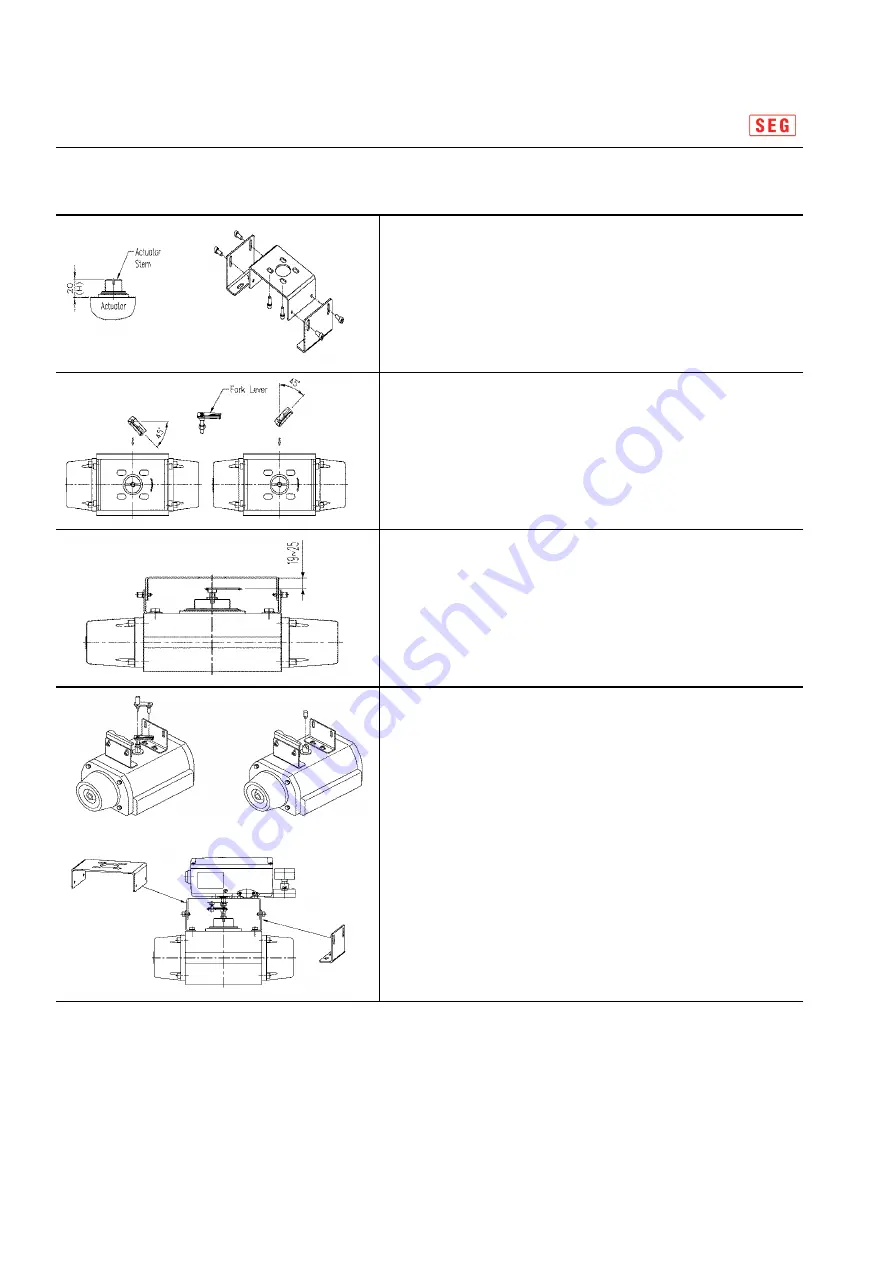

3.4.2 Rotary Positioner Installation Step

①

Connect upper/lower bracket assemblies onto an actutor

with bolts. Note the positioner manufacturer does not supply

bolts to fix an actuator.

②

With an actuator's initial start point of 0%, install the

fork lever as seen in figure according to the rotation

direction of stem.

Make sure the installation degrees of fork lever

Should be 45 degrees from the horizontal axis.

③

If fork lever position is setting , tighten the nuts,

which is assembled with the lower part of fork lever,

to an actuator stem firmly. At the moment, fork lever

upper side and the upper bracket's distance should be

19 to 25 mm each other.

Actuator

Lower/upper bracket

Clockwise / counterclockwise

Fork lever assembling height

setting

22/40

④

Attach the positioner onto upper bracket and fix it with bolts.

At the moment, insert the pin on the lower part of

the fork lever into the hole of fork lever so to be centered.

When tightening bolts, do not tighten ane bolt firmly

and after loosing 4 pcs of bolt slightly and

after checking positioner's connection, connect bracket

completely.

※

Namur type installation is very simple because there is

sufficient length and end of shaft is machined

so that it may be insert into actuator stem pin directly.

FORK LEVER TYPE

NAMUR TYPE

22/40

Содержание SP740 Series

Страница 14: ...Smart Positioner SP740 Series 2 10 2 SP740 Lever Type 14 40 Fig 2 6 SP740 Lever Type 14 40...

Страница 15: ...Smart Positioner SP740 Series 2 10 3 SP740 Fork Lever Type 15 40 Fig 2 7 SP740 Fork Lever Type 15 40...

Страница 16: ...Smart Positioner SP740 Series 2 10 4 SP740 Namur Type 16 40 Fig 2 8 SP740 Namur Type 16 40...

Страница 39: ...Smart valve positioner SP740 Series 10 LCD Operation Map 39 40 39 40...