31

13.1 Lubrication

Since your planer thicknesser is constructed of cast iron, which is a porous metal, care should

be taken when cleaning. Use mineral spirits and steel wool on all metal parts. Avoid contact

with anything moist. Do not set drinks on the table top or leave green wood on it. These will

leave permanent marks.

Waxing the table surface will help resist moisture, as well as reducing friction on the

workpiece. Avoid products that contain silicone, anti-slip additives or abrasives.

Clean the interior of the machine frequently to prevent the accumulation of chips and

sawdust around the motor and rise and fall mechanisms.

Once clean, lubricate moving parts using a lubricant that does not pick up a lot of sawdust.

Pay particular attention to the following: the drive chain, thickness table rise and fall

barrel, thickness table rise and fall screw, thickness table rise and fall gears, surface table

screw and slide assembly, fence table bar, fence swivel screw, and the front cutterblock

guard vertical support bar.

Powdered graphite, hard wax or white lithium spray is ideal. Do

not use an oil-based product. These will collect sawdust and congeal into a gummy

substance, making working parts hard to operate. Drive belts will also deteriorate if they

come into contact with oil.

13.2 Cutterblock and Bearings

The cutterblock needs very little maintenance, but it should be checked for wear, burrs and any

play in the bearings that the arbor rides in.

First check the cutterblock, the chipbreakers, and the cutterblock screws for dirt, burrs or

raised nicks. Slight imperfections can be removed carefully with a fine-cut file.

The cutterblock bearings are sealed for life and require no lubrication. To check their

condition, turn the block by hand while feeling for any roughness. Grasp the arbor on the drive

side of the block and gently pull up and down to check for any play. Roughness or slack in the

bearings means that they need to be replaced.

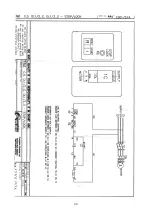

13.3 Vee Belts and Pulleys

The spindle is driven via an A64 vee belt and the feed mechanism by a flat belt. To

prevent loss of power and/or belt slip these belts should be correctly tensioned and

regularly checked for wear.

When the belts begin to show signs of wear replace them. Frayed belts will cause

vibration, putting unnecessary strain on the arbor bearings. Instructions on changing the

drive belt are as follows:

You will need an A64 vee belt, a rule, a 13mm spanner and a 19mm spanner.

Electrically isolate the machine and remove the back-guard. Next remove the gear train

(or banjo). To ensure that it is replaced correctly first take a measurement from the

machine side frame to the outside of the gear wheel (part no. PT9035). Remove the

chain. You may need to wedge the chain tensioning sprocket to do this. Next remove the

gear chain by undoing the 13mm fixing bolt located on the underside of the cast base

(part no. PT9010) and the flat belt. Replace the vee belt and then build the machine

Содержание PT255

Страница 36: ...36 14 0 PT255 Planer Thicknesser Parts Diagram ...

Страница 39: ...39 ...

Страница 40: ...40 ...