ATLANTIC 3000

3000mm Diameter Ocean Buoy

Latest products and information available at

www.sealite.com

25

Mooring Bridle Assembly:-

STANDARD PIN SHACKLES

1. Prop the bridle securely on some solid timbers (weight of the bridle plate is around 105

kg).

2. Connect the mooring swivel (not shown) to the central mooring point using a Ø44mm

Grade S shackle with pin tail down.

3. Connect each of the mooring links to the bridle arms using Ø44mm Grade S shackles

with pin tail down.

Figure 10 - Standard D-Shackles

Содержание ATLANTIC-3000

Страница 2: ...2 Version No Description Date Author Approved 1 0 Manual Launch October 2018 G Percy G Percy ...

Страница 8: ...8 Technical Drawings ...

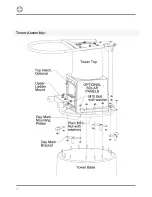

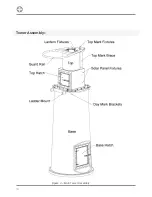

Страница 14: ...14 Tower Assembly ...

Страница 16: ...16 Tower Assembly Figure 4 Main Tower Assembly ...

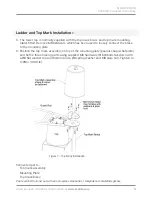

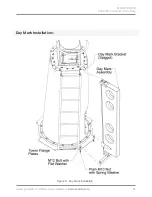

Страница 20: ...20 Ladder and Top Mark Installation Figure 6 Ladder Installation ...

Страница 32: ...32 Electronic Equipment Installation ...

Страница 34: ...34 Notes ...

Страница 35: ...ATLANTIC 3000 3000mm Diameter Ocean Buoy Latest products and information available at www sealite com 35 ...