4.6.

CONNECT THE TORCH CABLE TO THE WELDER.

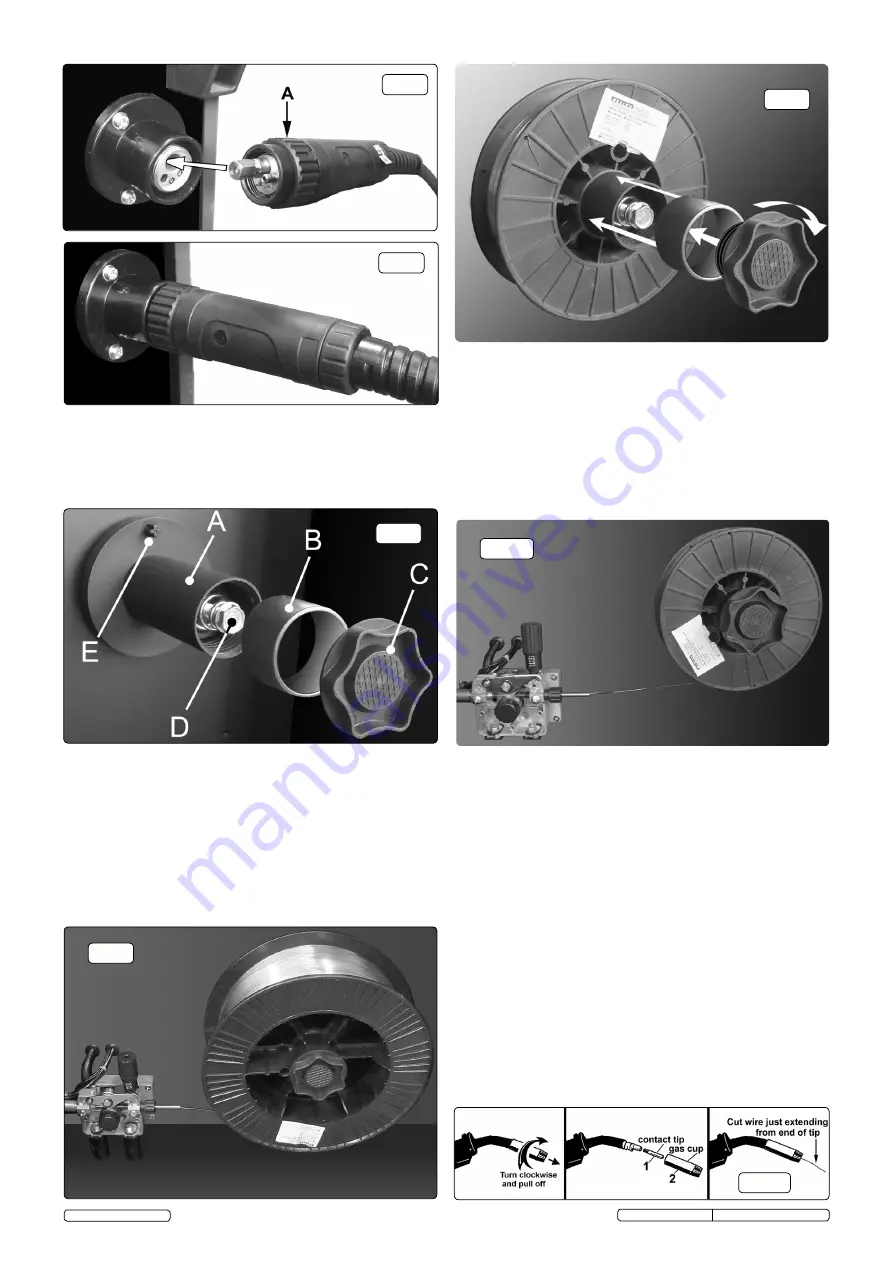

Align the pins

on the Euro connector with the socket on the welder front panel as

shown in fig.5. Push the connector into the socket and rotate the

locking ring (A) clockwise so that it draws the plug into the socket

as shown in fig.6.

Note: damage to torches and cables is not covered by warranty.

4.7.

FITTING A 15KG REEL OF WIRE.

Ensure that the wire diameter

used, is matched by the correct groove size in the drive wheel and

the correct tip size on the torch as well as the correct torch liner.

Failure to do this could cause the wire to slip and/or bind.

4.7.1

Unscrew the locking knob from the end of the spool holder (see

fig.7C) and remove the spacer (B). The spacer is not required for

15kg reels of wire. Slide the reel of wire onto the spool holder and

ensure that the clutch pin at the back of the spool holder (E)

engages into the guide hole in the wire reel moulding. This will

prevent the wire reel from freewheeling on the spool holder. Ensure

that the wire is coming off the bottom of the reel in the direction of

the wire drive unit as shown in fig.8 below.

4.8.

FITTING A 5KG REEL OF WIRE.

Ensure that the wire diameter

used, is matched by the correct groove size in the drive wheel and

the correct tip size on the torch as well as the correct torch liner.

Failure to do this could cause the wire to slip and/or bind.

4.8.1.

Unscrew the locking knob from the end of the spool holder (see

fig.7C) and remove the spacer. Slide the reel of wire onto the spool

holder and ensure that the clutch pin at the back of the spool holder

(E) engages into the guide hole in the wire reel moulding. This will

prevent the wire reel from freewheeling on the spool holder. Slide

the spacer onto the spool holder and retain it by screwing the knob

into place as shown above in fig.9. Ensure that the wire is coming

off the bottom of the reel in the direction of the wire drive unit as

shown in fig.10.

fig.5

fig.6

fig.7

fig.8

fig.9

fig.10

4.9.

FEED WIRE THROUGH TO TORCH.

Referring to fig.12 open the wire

feed mechanism by pushing the locking/wire tension knob (1) down to

the right allowing the pressure roller carrier (2) to spring up revealing

the feed roller. Ensure that the required feed groove (0.6 or 0.8) is in

line with the wire path. See Section 4.12 on how to reverse or change

the roller.

4.9.1

Release the wire from the reel and cut off any bent portion ensuring

that there are no burrs left on the end of the wire. Keep the wire under

tension at all times to prevent it uncoiling.

4.9.2

Straighten about 40-50mm of wire and gently push it through the

flexible metal sheathed cable (3) and through the 6 or 8mm feed roller

groove and on into the torch cable liner.

4.9.3

Push down the pressure roller carrier onto the wire feed roller and hold

it down. Lift up the locking/wire tension knob so that it enters the slot

in

the pressure roller carrier and snaps into the indent in its top surface.

See fig.13. Rotate the tension knob to a medium setting i.e. between 2

and 3.

4.9.4 Remove gas cup (fig.11-2) and contact tip (1) from end of torch as follows:

a) Take torch in left hand with the torch tip facing to the right.

b) Grasp gas cup firmly in your right hand.

c) Turn gas cup clockwise only and pull it off end of torch tip.

WARNING! do not turn gas cup anti-clockwise, as this will damage

the internal spring.

d) Unscrew copper contact tip (right hand thread) to remove.

4.9.5 Check welder is switched off “0”, and that the earth clamp is away

from the torch tip. Connect the welder to the mains power supply and

set the voltage switch to one.

fig.11

Original Language Version

© Jack Sealey Limited

SUPERMIG180.V3 Issue No:5(D) - 11/11/16