5.1.2

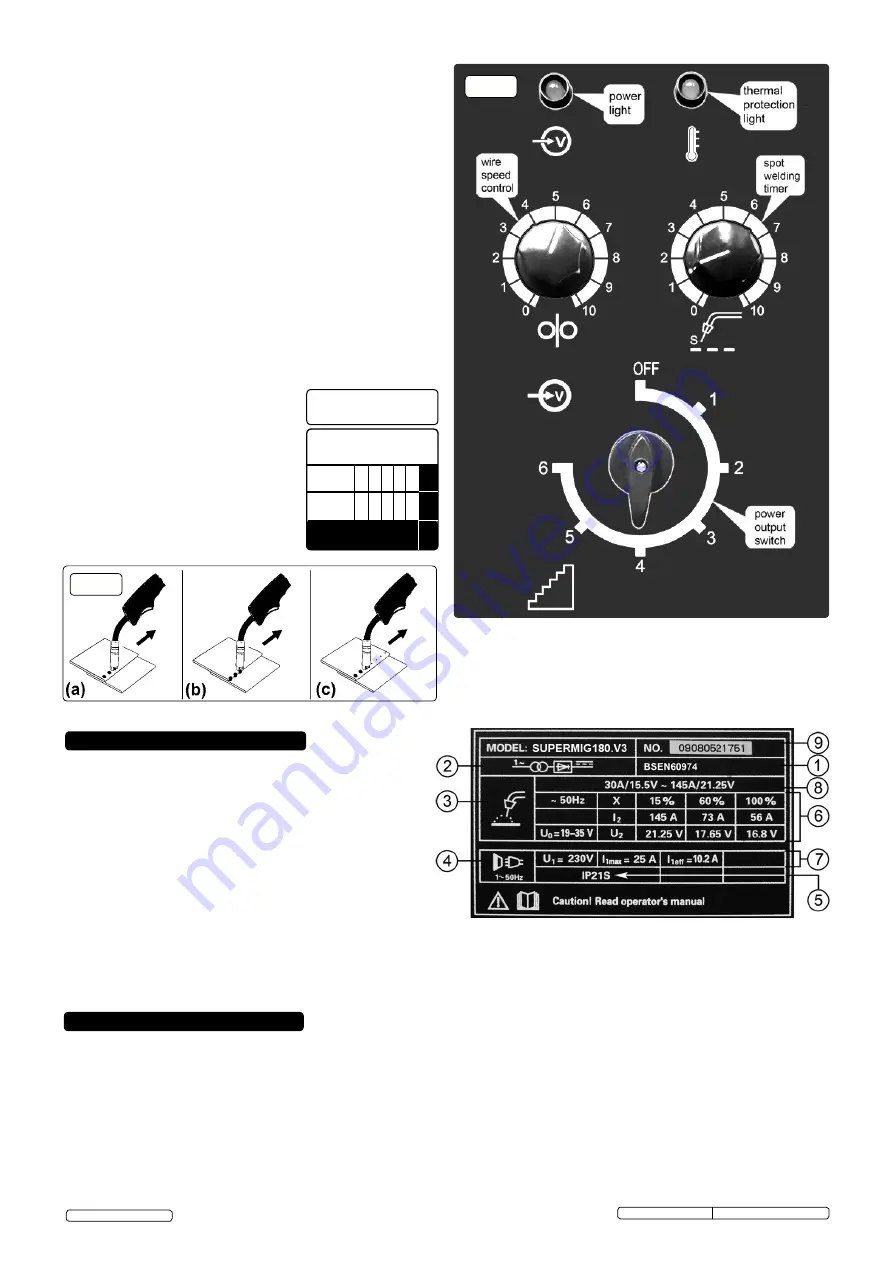

power Output switch.

Set the switch to position 1 or 2 for welding

up to 2mm thickness. Use settings 3,4,5,6. for thicker welds.

5.1.3 S

etting the welder controls.

In principle, the lower the amperage

required, the slower the wire speed. See setting chart below for

voltage and corresponding wire speeds. Note: these settings are only

a guide and will vary according to the operator's experience.

5.1.4

Welding mild steel.

To weld mild steel you can use CO² gas for most tasks where spatter

and the high build up of weld do not pose a problem. Welding with a

long arc reduces penetration and widens the arc. This in turn results

in more spatter. A long welding arc can be appropriate for welding butt

joints in thin materials. Welding with a short arc, at the same weld

settings, results in greater penetration and a narrower weld and

reduces the amount of spatter. To achieve a consistent spatter free

and flat weld, you must use an Argon/CO² mixture.

5.1.5

To weld aluminium use:

Argon gas,

0.8mm Contact Tip,

0.8mm Aluminium Wire,

5.1.6

Overload protection.

Thermostatic overload protection is provided.

When an overload has occurred, leave the unit to cool. The

thermostat will automatically reset the unit when the temperature has

returned within limits

5.1.7

Spot Welding.

Spot welding may be carried out as shown in fig.16.

It will be necessary to fit a spot welding gas cup.

(a) Overlapping metal sheets with a

maximum thickness of 0.8 mm may be

welded as indicated.

(b) Alternatively they may be welded

edge to surface as indicated.

(c) For thicker sheet pre drilled holes

holes may be employed.

5.1.8 Use the wire feed control in conjunction

with the spot weld timer beside it. To

activate the timer turn the knob clockwise.

The settings indicated in the black portion

of the chart are for guidance only and

may vary with operators experience.

7.1.

WIRE FEED UNIT

Check the wire feed unit at regular intervals. The feed roller wire guide plays an important part in obtaining consistent results. Poor

wire feed affects welding. Clean the rollers weekly, especially the feed roller groove, removing all dust deposits.

7.2.

TORCH

Protect the torch cable assembly from mechanical wear. Clean the liner from the machine forwards by using compressed air. If the liner is

clogged it must be replaced.

7.3.

CHANGING FEED ROLLER

(See Section 4.12)

7.4.

CONTACT TIp

The contact tip is a consumable item and must be replaced when the hole becomes enlarged or oval. The contact tip MUST be kept free

from spatter to ensure an unimpeded flow of gas. Refer to fig.11 and section 3.9 for removal and replacement.

7.5.

GAS CUp

The gas cup must also be kept clean and free from spatter. Build up of spatter inside the gas cup can cause a short circuit at the contact tip

which will result in either the fuse blowing on the printed circuit card, or expensive machine repairs. To keep the contact tip free from spatter, we

recommend the use of Sealey anti-spatter spray (MIG/722308) available from your Sealey Dealer. Refer to fig.12 and section 4.9 for removal and

replacement.

7.6.

REpLACING THE LINER

Wind the wire back on to the spool and secure it. Unscrew the torch from the machine and undo the brass nut. The liner should

now be visible. Pull it out and replace with a new one.

On the front of the welder is the ratings plate, giving the

following data:

1 -

The standard relating to the safety and construction

of arc welding and associated equipment.

2

- Single phase transformer - rectifier.

3 -

Welding with a continuous flow of welding wire.

4 -

Single-phase AC supply.

5 -

Rating of internal protection provided by casing.

6 -

Output

U0: Rated minimum & maximum no load voltage.

I2, U2: Current and corresponding voltage.

X: Welding ratio based on a 10 minute cycle. 20% indicates 2 minutes welding and 8 minutes rest, 100% indicates continuous welding.

7 -

Mains Supply U1: Rated supply voltage and frequency. Imax: Maximum current.

I1eff: Maximum effective current.

8 -

Welding current range.

9 -

Serial Number. Specifically identifies each welder.

6. RATINGS pLATE

Wire 0.6mm Steel

Argon / CO2 Mix

Voltage

Step:

1 2 3 4 5

6

Wire

Speed:

5 6 7 8 9

10

SETTINGS SHOWN

AS GUIDE ONLY

Spot Welding Timer

6

6

10

fig.15

fig.16

7. MAINTENANCE

Original Language Version

© Jack Sealey Limited

SUPERMIG180.V3 Issue No:5(D) - 11/11/16