5. MAINTENANCE & STORAGE

p

p

WARNING! Before carrying out routine maintenance or inspection, vent any pressure

remaining in the hose.

5.1

The hose reel does not require special maintenance as it is lubricated for life. To ensure

reliable operation, clean the hose and casing regularly.

DO NOT

spray or wet the product, but

clean with a cloth and warm water.

DO NOT

use solvents or detergents, as these may

permanently damage the plastic .

5.2

There are no user serviceable parts. All maintenance and repairs which require the case to

be opened or dismantled should be carried out by an authorised service agent only.

p

WARNING!

DO NOT

dismantle the hose reel casing, or attempt to remove the screws and covers

on the sides. To do so may result in damage to the appliance and/or personal injury and will

invalidate the warranty.

STORAGE:

Should you wish to store the air hose, ensure it is clean and dry. Place the item in a dark, safe, dry, childproof location, where the

temperature will remain reasonably stable.

DO NOT

store in a nylon, or plastic, bag as this will encourage condensation.

NOTE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT:

No liability is accepted for incorrect use of this equipment.

WARRANTY:

Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION:

For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

SA88 - 1 - 160103

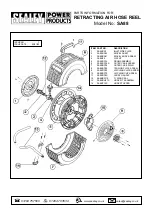

3.2.3

Screw fix the bracket to the chosen surface using fixings that are appropriate to the substrate and

strong enough to carry the weight of the reel plus the working strain exerted on it when the hose

is pulled out. When fixing to a vertical surface ensure that the bracket is vertically aligned.

3.2.4

Align the tubular bracket mountings on the reel with the holes in the mounting bracket and slide

the swivel tube through both items to fix the reel to the bracket. Ensure that the retaining flange

on the tube is at the top of the bracket when the reel is mounted vertically.The swivel tube for the

standard bracket is pierced at one end so that a padlock can be attached to it for security

purposes.

3.2.5

Connect the air supply to the reel using a flexible hose sufficiently long to allow the reel to swivel

180

O

from side to side.

3.2.6

When the reel is positioned overhead the swivelling action can be locked by the use of the

steady bracket provided (as shown in fig.5-A). The steady bracket is positioned between the

main casing and the mounting bracket and is held in position when the swivel tube is inserted.

The steady bracket is not recommended for wall mounting.

A

fig 5

4. OPERATION.

6. TROUBLESHOOTING.

4.1

The hose reel has two modes of operation, automatic latching and free run mode. These

modes are selected by sliding the mode switch from side to side as indicated in fig.6. The mode

selected will become effective after at least 12 of hose has been pulled from the reel.

4.2

Automatic latch mode.

The hose can be pulled continuously from the reel and will only latch

when allowed to run back slowly to the nearest latch interval. ( The hose will latch every 18.) To

rewind the hose pull it out from the reel by 12 and release it quickly to activate the rewind

mechanism. Guide the hose back into the reel to avoid bunching.

4.3

Free run mode.

The hose will not latch when pulled out. To rewind reduce the tension and

guide the hose slowly back into the reel to avoid bunching.

p

WARNING!

Do not let go of the hose during rewind in either mode as an uncontrolled rewind

may result in injury to persons in the path of the hose and/or damage to the reel.

fig 6

PROBLEM

POSSIBLE CAUSE

SOLUTION

Hose will not retract. Hose bunching within reel.

Pull hose out of reel and guide back in.

Spring tension too tight.

Have spring tension adjusted by authorised service agent..

Replacement hose too heavy.

Have correct hose fitted by authorised service agent..

Reel will not latch.

Reel mounted upside down.

Reverse reel on bracket.

Releasing tension too quickly.

Release tension more slowly.

Broken latching pawl or mode switch. Have broken part replaced by authorised service agent..

Reel leaks.

Damaged hose.

Have new hose fitted by authorised service agent..

Loose air connection.

Tighten fitting.

Worn swivel seals.

Have new seals fitted by authorised service agent.

www.sealey.co.uk

01284 757500

01284 703534

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk.

Web