Page 24

Page 24

7.

Using the same carafe, prepare again 500

ml of warm water (40-50

°

C) and 15 ml of

Scotsman Sanitizing product and pour of the

solution on the internal sides of the storage bin.

8.

Using a sanitised disposable cloth, clean the

ice bin and rinse with clean water.

9.

Close the funnel plug and reinstall all the

previously removed panels and parts by following

the procedure in reverse order, paying attention

that both the steel bottom and the upper shaft of

the blade are properly seated.

10. Remove, clean and reinstall the air filter located

on the right side panel, then open the water tap.

11. Remove, clean and re-install the snorkel located

in the water dispensing tube using the special

key (P/N SC 651647 02) supplied to all DXN.

NOTE. Once the cleaning operations are

completed, switch on the equipment; the ice

production process will start after a delay of

ten minutes. Make sure that the first produced

ice doesn’t taste slightly acid; in any case

empty the bin by pressing the dispensing

button and dispose of the ice produced during

the first 10 minutes.

D.

T WICE A YEAR MAINTENANCE

After six months of operation of the unit’s

compressor, the Dispenser will indicate the need

to carry out the cleaning of the water circuit and

some checks of the machine.

On the display will appear a “CLE” as a Cleaning

Remind ensuring in the meantime the standard

operation of the machine.

The following maintenance procedure should be

performed every time the Cleaning Remind

appear by an authorized Scotsman Service.

1. Check and clean the water line strainer.

2. Remove the cover from the float reservoir -

care to do not damage the two water sensors

- and depress the float to make sure that a full

stream of water enters into the reservoir.

3. Check that the icemaker is levelled in side to

side and in front to rear directions.

4. Check that the water level in the water reservoir

is below the overf low but high enough that it

does not run out of the spout opening.

NOTE. The float must close positively the

incoming water flow when the rubber housed

in the setting screw, is perpendicular to the

water nozzle.

5. Clean the water system, water reservoir and

the interior of freezing cylinder using a solution

of SCOTSMAN Ice Machine Cleaner.

Refer to following procedure (E) cleaning

instructions and after cleaning will indicate

frequency and procedure to be followed in

local areas.

NOTE. Cleaning requirements vary according

to the local water conditions and individual

user operation.

6. If necessary, polish the two sensor rods

secured to the float reservoir cover, heavy

scale sediment on them can be removed with

the help of a bit of SCOTSMAN Cleaner.

7. Check for water leaks and tighten drain line

connections. Pour water into the drip tray to

be sure that drain line is open and clear.

Touch Version

Touchless Version

Содержание DXN 107

Страница 2: ...Page 3 Page 3 ...

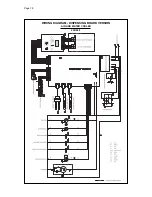

Страница 19: ...Page 18 Page 18 WIRING DIAGRAM DISPENSING BOARD VERSION AIR AND WATER COOLED 230 50 1 ...

Страница 20: ...Page 19 Page 19 ...