Assembly

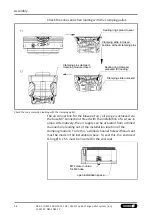

Air bleeding for the piston chamber

When connecting the quick-change pallet systems, it is important

to note that it is only possible to completely bleed the air from the

piston chamber via the air connections during the locking process.

The relevant valves or shut-off valves should therefore be

equipped with load relief.

This also applies to the turbo connection.

If the turbo connection

is not used, the relevant side of the piston must have a way of

being ventilated.

This is best done via the turbo connection itself.

For the NSE3 138, a ventilation option for the cylinder chamber

can be created by removing the M4 x 4 set-screw in the cover of

the clamping module. The following views illustrate the air bleed

options.

Air bleeding via turbo connection, air bleeding via the cover

Applies to NSE3 138-K /-V1-K /V4-K /-P-K

Air bleeding and ventilation via turbo connection

hose-free

direct

connection for

turbo function

Air bleeding and ventilation via the cover and open

ventilation channel in the installation space

Caution: The set-screw in the cover must

be removed for air bleeding and ventilation

Ensure air bleeding and

ventilation via open recess

Air bleeding via the cover in the version with a cone seal

Applies to NSE3 138-K /-V1-K /V4-K /-P-K

Air flow for

exhaust function

Caution: The set-screw

must be removed from

the cover of the quick-change

pallet system for air bleeding

(without turbo function)

Air supply at the cone

seal via the seal on the

base side (max. 2 bar)

Direct connection

from installation

space with seal to

cone seal via O-ring

Ø 6 x 5.5

Air bleeding and ventilation

for actuation (without turbo

function) in open recess

guaranteed

Version 2 via ventilation hole

Air bleeding via turbo connection.

Applies to NSE3 138-K / -V1-K / V4-K / -P-K with air supply at the cone seal

23

08.00 | NSE3 138, NSE-T3 138 | VERO-S quick-change pallet system | en |

1152197 -NSE3 NSE-T3