_________________________________________________________________________________________

schunk.com

XND.00005.022_A – 10/2018

31

3.1.4

Removing the spindle assembly

Use the clamping lever to move the hexagonal head

of the spindle to the left-hand stop and adjust the

clamping width to min. 30 mm.

Remove the knurled pin (pos. 120) from the

clamping lever and turn it into the thread of the

couplimng bolt (pos. 70) through the hole in the

base plate and pull the coupling bolt out.

The spindle assembly can now be pulled out for

cleaning or releasing the base plate.

Note: it is also possible to remove the coupling bolt in vertical position. To do that

the fixed jaw has to be removed and the coupling bolt has to be brought into the

vertical position by turning the clamping lever to the right by 90°. After that you can

remove the bolt using the disassembly tool.

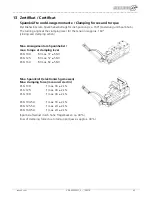

3.1.5

Fitting the spindle assembly

Insert the spindle assembly into the base plate.

Turn the knurled knob in order to ensure that the

holes in the mechanical force cassette and the

spindle assembly are lined up for inserting the bolt.

Use tool to insert coupling bolt in lateral hole.

Check whether the locking of the bolt in the pull

rod can be felt.

The marking at the knurled pin (pos. 120) must be

flush with the side surface of the base plate. (this

varies according to the size of the machine)

Visual check from above.

Remove the knurled pin and turn on to the

clamping lever.

3.1.6

Changing jaws

Release screws and remove the jaws.

Clean and oil the contact surfaces, e.g. with MOTOREX Supergliss 68 K to ISO VG 68.

Insert the jaws and tighten crosswise using original screws.

Use 60 Nm to tighten jaws of widths 100 and 125 and use 150 Nm for 160 jaws.

3.1.7

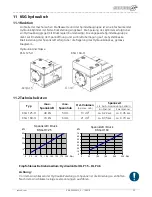

Cover sheets

Cover sheets are not mandatory because the spindle does not turn during the clamping

process.

A set of cover sheets is supplied for additional protection.

Select the appropriate sheet sizes suitable for the clamping range and engage in the V-groove

in the base plate or, with KSG 160, slide in from the rear and engage in the nut.

For larger clamping ranges it is possible to combine several sheets. The cover sheets can be

removed by gripping from below and pulling upwards or by removing the spindle assembly.