Maintenance

26

04.00 | KGG 220 - 280 | Assembly and Operating Manual | en | 389168

7 Maintenance

7.1 Notes

Original spare parts

Use only original spare parts of SCHUNK when replacing spare and

wear parts.

7.2 Maintenance interval

NOTICE

Material damage due to hardening lubricants!

Lubricants harden more quickly at temperatures above 60°C,

leading to possible product damage.

•

Reduce the lubricant intervals accordingly.

Interval [Mio. cycles]

2

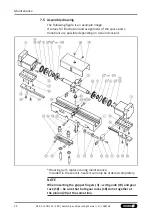

7.3 Lubricants/Lubrication points

SCHUNK recommends the lubricants listed.

During maintenance, treat all greased areas with lubricant. Thinly

apply lubricant with a lint-free cloth.

Lubricant point

Relevant size/variant

Lubricant

Metallic sliding

surfaces

all sizes and variants

(except H1G)

microGLEIT GP 360

Variant H1G

Klübersynth UH1

14-151 *

All seals

all sizes and variants

(except H1G)

Renolit HLT 2

Variant H1G

Rivolta F.L.G. GT-2

*

Bore hole at the

piston

all sizes and variants

(except H1G)

Renolit HLT 2

Variant H1G

Rivolta F.L.G. GT-2

*

* Note: The product contains optional H1 certified lubricants.

The

requirements of standard EN 1672-2:2020 are not fully met.

NOTE

• Change contaminated food-compliant lubricant.

• Observe information in the safety data sheet from the lubricant

manufacturer.