82

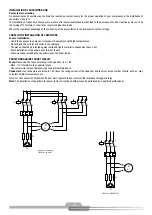

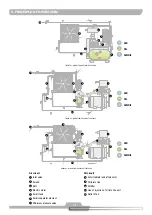

5. PROCEDURE FOR DRAINING THE CONDENSATE (WATER) FROM THE AIR/OIL TANK

The draining of the condensate of the air/oil tank must be performed daily. In order to drain the condensate of the air/oil tank, follow the

procedures below and check Figures 13.10 and 13.11.

- See item 1 - Procedures before beginning maintenance.

- Turn the compressor off and wait for 1 (one) hour for the condensate to settle on the bottom of the tank.

- Open the drain valve

4

and collect the condensate in a container. Close the drain valve as soon as oil starts coming out of the tank.

6. PROCEDURE FOR REPLACEMENT OF THE OIL FILTER

Wait for the compressor to cool down before beginning the work. The oil filter cannot be reused and must be disposed according to the

local regulations.

In order to change the oil filter, follow the procedures below and check Figures 13.8 and13.9. The period for changing the oil filter is indicated

in Table 13.3

- See item 1 - Procedures before beginning maintenance.

- Remove the element used 1.

- Install the new element 1.

- Update the information of number of hours for the next change of oil filter on the electronic interface of the compressor. The number to be

set is indicated in the parameter table attached to the information folder of your compressor. (Procedure necessary for electronic compres-

sors only).

- Make sure the sealing of the air filter is well seated on the fastening head.

Note:

The first change must be performed with 300 hours.

7. PROCEDURE FOR CHANGING THE LUBRICANT OIL

Use LUB SCHULZ or LUB SCHULZ SYNTHETIC oil for rotary screw air compressor only. Do not mix different kinds of oil. The oil is still hot

when the compressor is just turned off. Do not open the filling plug if the tank is pressurized. Dispose the oil according to the local regula-

tions.

In order to change the oil, follow the procedures below and check Figures 13.10 and 13.11. The period for changing the oil is indicated in

Table 13.3

- See item 1 - Procedures before beginning maintenance.

- Turn off the compressor and wait for at least 5 (five) minutes for the elimination of the pressure from the system. The air/oil tank has a

pressure gauge. Check if the tank is completely depressurized before performing the next step.

- Open valve

4

and collect the used oil in a container. Close the valve at the end of the draining.

- Open the filling plug

2

and fill with LUB SCHULZ or SYNTHETIC LUB SCHULZ oil until the oil level reaches the lower part of the filling plug.

- Close the filling plug after the filling. It is not necessary a strong fastening, since the plug is self-sealing.

Note:

- In the air/oil tank is a tag that indicates the LUB SCHULZ oil for rotary screw air compressor which comes in your compressor from factory.

You find this oil in SCHULZ AUTHORIZED DEALER. This compressor may operate with mineral oil* and atoxic synthetic oil*.

- We recommend using the same oil. Changing the kind of oil can cause contamination because of chemical incompatibility, reducing the

useful life of the oil and producing lubrication problems.

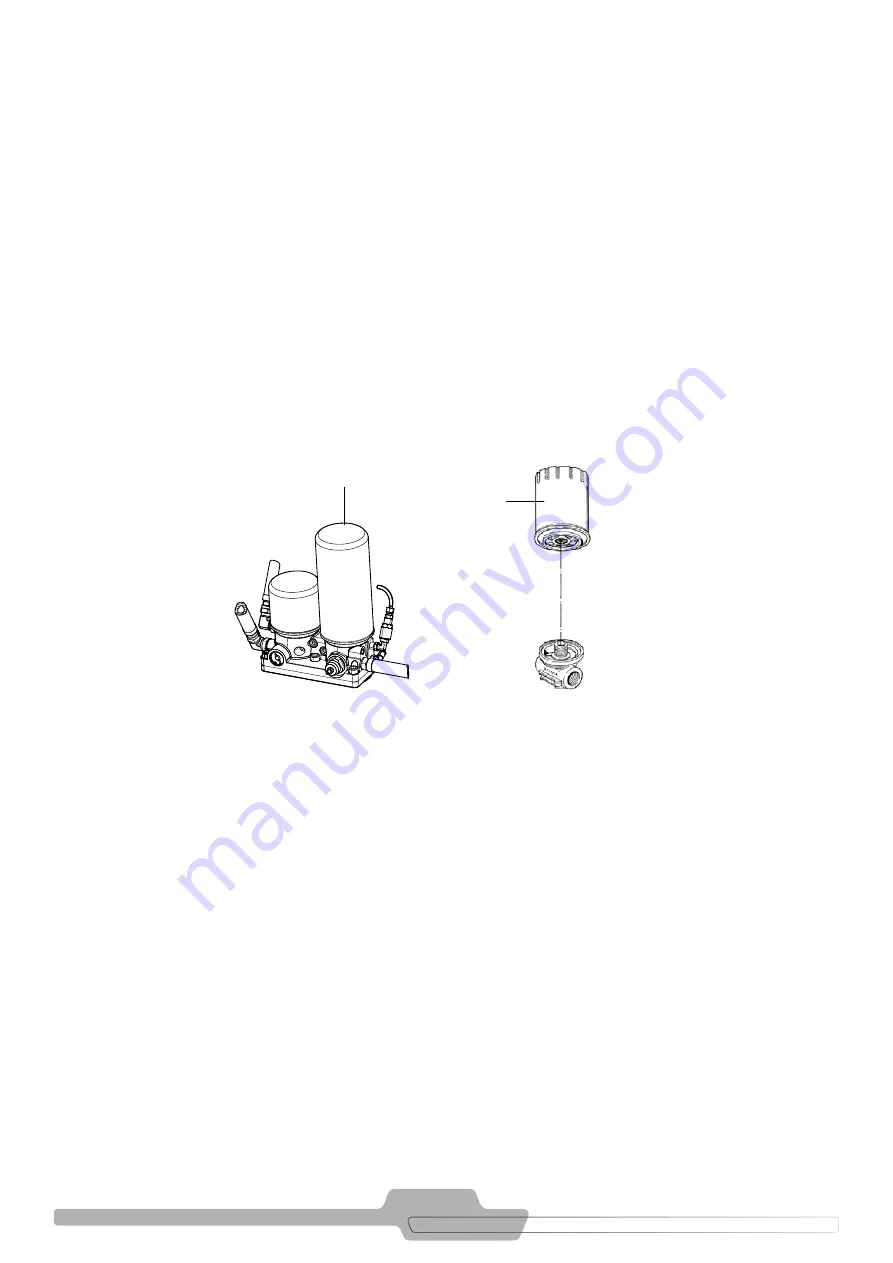

FIGURA 13.8 - SRP 3005 TO SRP 3010II

FIGURA 13.9 - FROM SRP 3010

1

1