UNM / CPM / ZPM / SEM - OF

II/9

GB

2.7 Decommissioning

Store the compressor in a dust-free and dry

area where it is not exposed to high tem-

perature fluctuations.

2.7.1 Environment

Do not dispose of the device in

household waste!

Recycle de-

vices, accessories and packaging.

Observe applicable national regulations.

EU only:

In accordance with European Di-

rective on waste electrical and electronic

equipment and implementation in national

law, used electric power tools must be col-

lected separately and handed in for environ-

mentally friendly recycling.

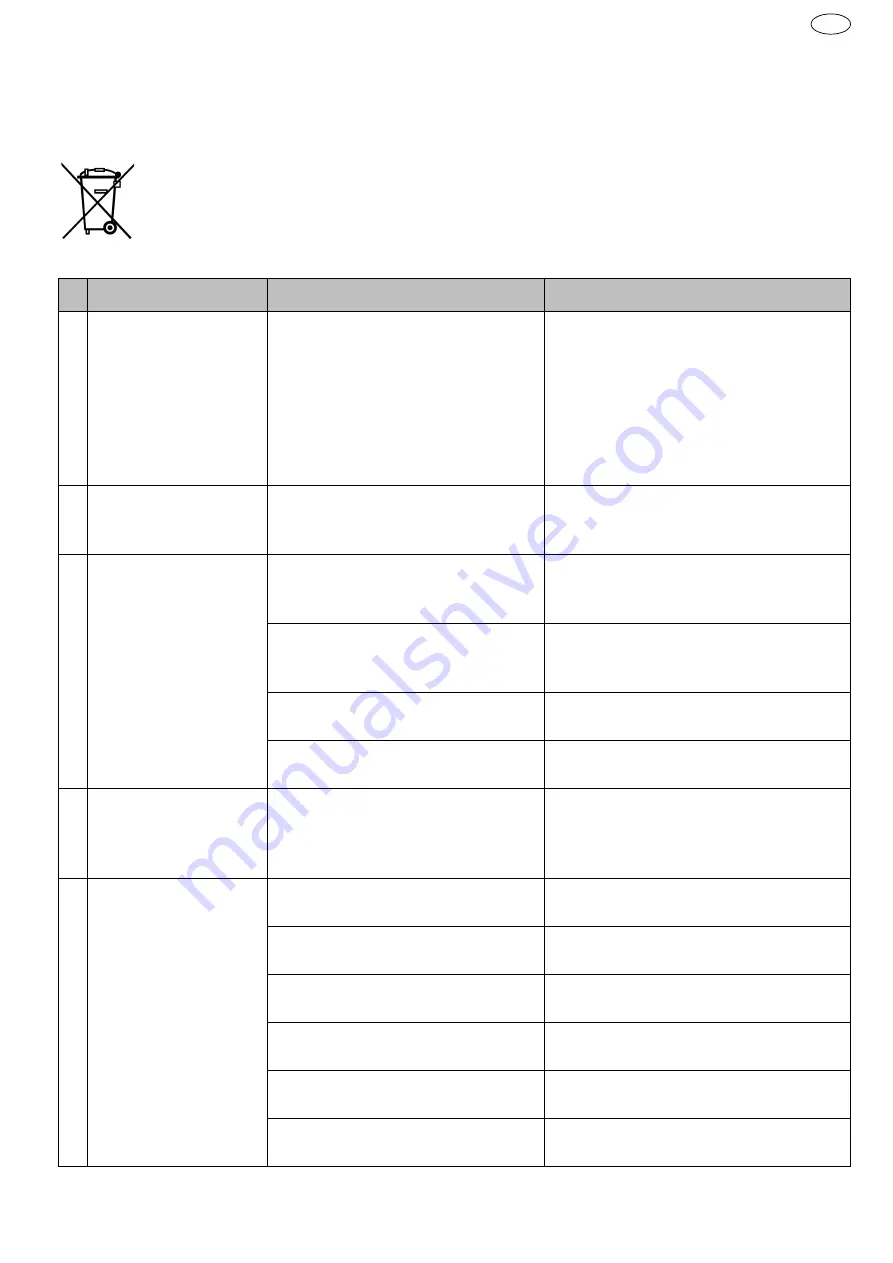

2.8 Troubleshooting

Problem

Cause

Remedy

A Protective motor

switch interrupts

power supply

In case of malfunctions (e.g.

overheating; low voltage;

extension cable too long or

with incorrect cross-section),

the protective motor switch is

tripped.

Switch off the compressor. Wait a

short while. Actuate the protec-

tive motor switch is available.

Switch on the compressor.

Protective motor switch trips

again: switch off compressor.

Disconnect the power supply.

Contact the service partner

B Pressure relief does

not function

Power failure / undervoltage in

mains with compressor

switched on

Switch off the compressor. It de-

pressurises. Switch on the com-

pressor

C Compressor does

not start when

switched on.

Vessel pressure is higher than

switch-on pressure.

Relieve pressure in the vessel

until the pressure switch is acti-

vated automatically.

Power supply faulty.

Have the power supply checked

by a qualified person (service

partner).

Protective motor switch inter-

rupts power supply.

See item A.

Pressure switch defective

Have the pressure switch

changed by a qualified person.

D Compressor starts

up briefly / buzzes

and then switches

off automatically

Mains connection cable longer

than permitted or the cross

section is too small

Check connection cable length

and cable cross-section (see

Chap. 2.4.4)

E Compressor runs

continuously

Intake filter badly contami-

nated

Clean or replace

Air consumption of compressed

air tools is too high

Check air consumption. Contact

the service partner

Leakage at compressor

Locate leak, contact service part-

ner

Excessive condensate in the

tank

Drain the condensate (see

Chap. 2.6.5)

Compressed air line leaky

Check the compressed air net-

work, seal leak

Condensate drain valve is open

or missing

Close or replace