II/8

UNM / CPM / ZPM / SEM - OF

GB

2.6 Maintenance

2.6.1 Before each maintenance task

1. Swtich on the compressor at the ON/OFF

switch (item 10). Disconnect the power

supply.

2. Depressurise the compressor: using the

blow gun, blow out all pressure from the

vessel.

2.6.2 Cleaning the compressor

• Clean the cooling fins on the cylinder, cyl-

inder head and aftercooler using com-

pressed air.

• Clean the fan impeller cover on the motor.

2.6.3 Clean FDM insert

1. Depressurise vessel of FDM.

2. Hold a suitable vessel under the conden-

sate drain. Drain condensate.

3. Disassemble vessel of FDM. Unscrew the

mounting screw of the filter insert by

screwing anticlockwise (Fig. 4a).

4. Remove the filter insert, clean in soapy

water (max. 50 °C).

5. Installation is in reverse order.

2.6.4 Draining condensate from FDM

Draining semi-automatically:

Rotate the

condensate drain valve 1/4 turn anticlock-

wise. Under 1 bar: condensate drains. (Fig-

ure 4a)

Draining manually:

Rotate the condensate

drain valve clockwise and push it up. Con-

densate drains.

2.6.5 Draining condensate from pres-

sure vessel

Dispose of condensate in accordance with

local specifications!

Caution:

Wear safety glasses!

1. Place a suitable vessel under the conden-

sate drain.

2. In order to drain condensate, the vessel

pressure must be 2 - 3 bar.

3. Open condensate drain valve (item 09).

4. Close condensate drain valve again fol-

lowing condensate drainage.

2.6.6 Checking the screw fittings

• Check that all the screw connections are

secure, and retighten them if necessary.

2.6.7 Cleaning the intake filter

See instruction manual, part 1.

Do not purge the intake opening. No for-

eign objects may enter.

Never operate the compressor without an

intake filter.

2.6.8 Cleaning/replacing the check

valve

1. Unscrew the locking screw (Figure 6a).

2. Clean insert, replace in case of damage,

squeezing or hardening.

3. Clean seat, replace complete check valve

if damaged.

2.6.9 Replacing the safety valve

1. Unscrew the safety valve (item 11) anti-

clockwise.

2. Apply medium-strength thread-locking

fluid, e.g. Loctite® 243, to the thread of

the new safety valve or wrap Teflon tape

around the valve.

3. Tightly screw the new safety valve in

clockwise.

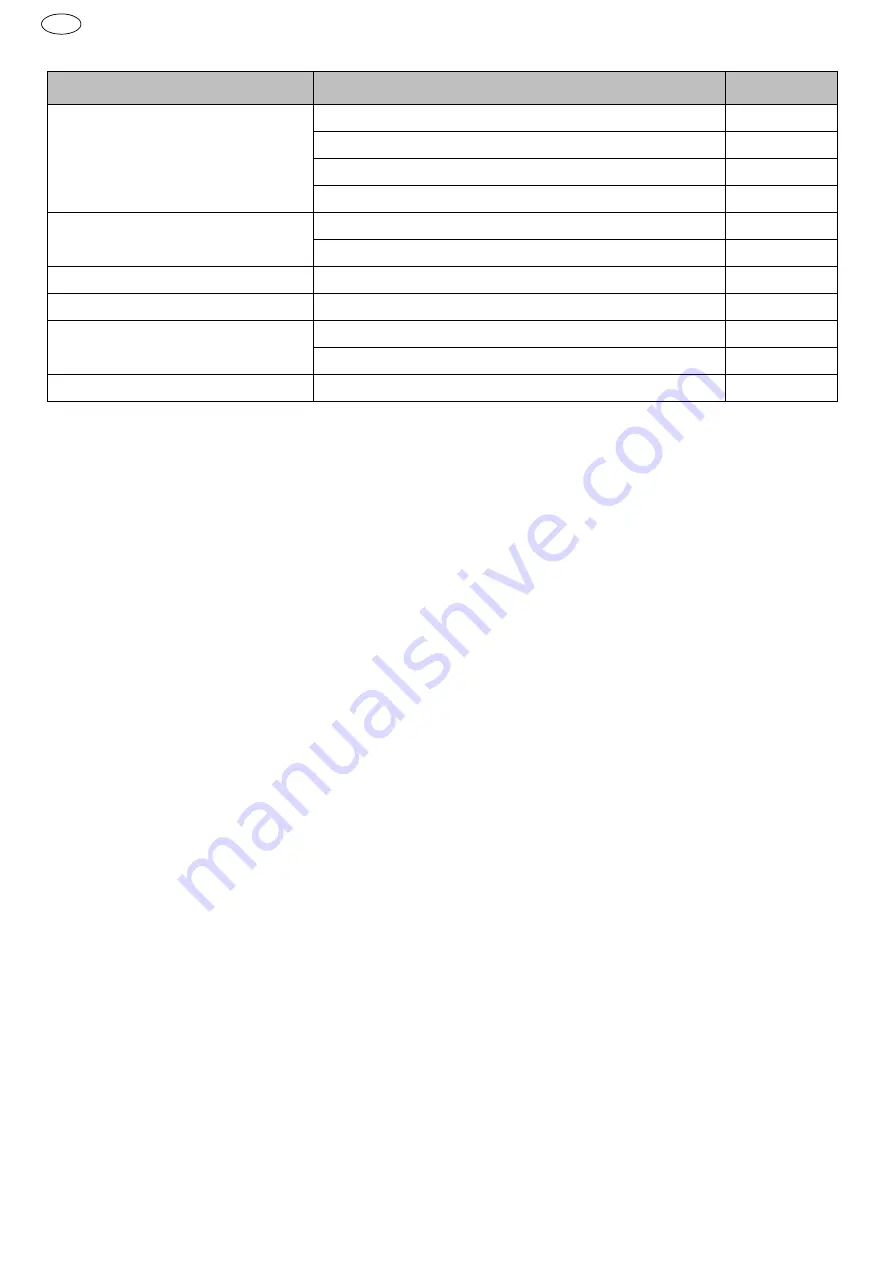

Interval / No later than

Tasks

See chap.

-- / As needed

Clean compressor

Clean filter insert (FDM)

Clean intake filter

Change intake filter

-- / after each use

Drain condensate from pressure vessel

Drain condensate from FDM

Once after 10 h / --

Check screw connections

-- / Weekly

Check intake filter

annually / --

Replacing the check valve

Check screw connections

2,500 h / After 5 years

Change safety valve