14

Operating instructions

Multifunctional safety controller

PROTECT SELECT

PROTECT SELECT OEM

EN

First and second safety areas

The inputs I16 and I17 (default setting: emergency stop) switch off all

the parent outputs Q0 to Q2 and from QR1 to QR2.

The condition START / RESET via the input I15 is permanently

assigned to the inputs I16 to I17.

In addition, the inputs can be changed as individual sensors I16 and I17

together with the default setting "Emergency Stop command device".

Digital inputs I00, I01, I13, I12, I15

• Input I00 (RESET), First safety area:

Restart condition of the safety sensors, connected to the inputs

I02 to I05.

• Input I00 (RESET), Second safety area:

Restart condition of the safety sensors, connected to the inputs

I06 to I11.

• Input I12 (feedback circuit). First safety area:

Feedback circuit from the actuators (e.g. guards, drive regulator,

inverter, valve terminal etc.) is switched as an additional condition to

the function macro.•

• Input I13 (feedback circuit). Second safety area:

Feedback circuit from the actuators (e.g. guards, drive regulator,

inverter, valve terminal etc.) is switched as an additional condition to

the function macro.•

• Input I15 (RESET for the Emergency-Stop command device with a

higher priority):

Restart condition after the Emergency-Stop control device has been

actuated.

High priority for all safety areas: Signalling output Y3

• Signaling output Y3:

for the information transfer that an error has occurred with an error

message or warning with a warning message on the display. This

message output can also be used to control a corresponding fault or

warning message lamp.

1. Safety area: Safe semi-conductor outputs Q0/Q0N

• Stop 0 or Stop 1:

All semiconductor outputs are linked to a safe timer (Timer Off Delay).

Stop 0: Timer = 0 seconds (Default value)

Stop 1: Timer should be actively adjusted to 0 seconds

2. Safety area: Safe semi-conductor outputs Q2, Q3

• Stop 0 or Stop 1:

All semiconductor outputs are linked to a safe timer (Timer Off Delay).

Stop 0: Timer = 0 seconds (Default value)

Stop 1: Timer should be actively adjusted to 0 seconds

2. Safety area: Safe relay outputs QR1, QR2

• Stop 0 or Stop 1:

All relay outputs are linked to a safe timer (Timer Off Delay).

Stop 0: Timer = 0 seconds (Default value)

Stop 1: Timer should be actively adjusted to 0 seconds

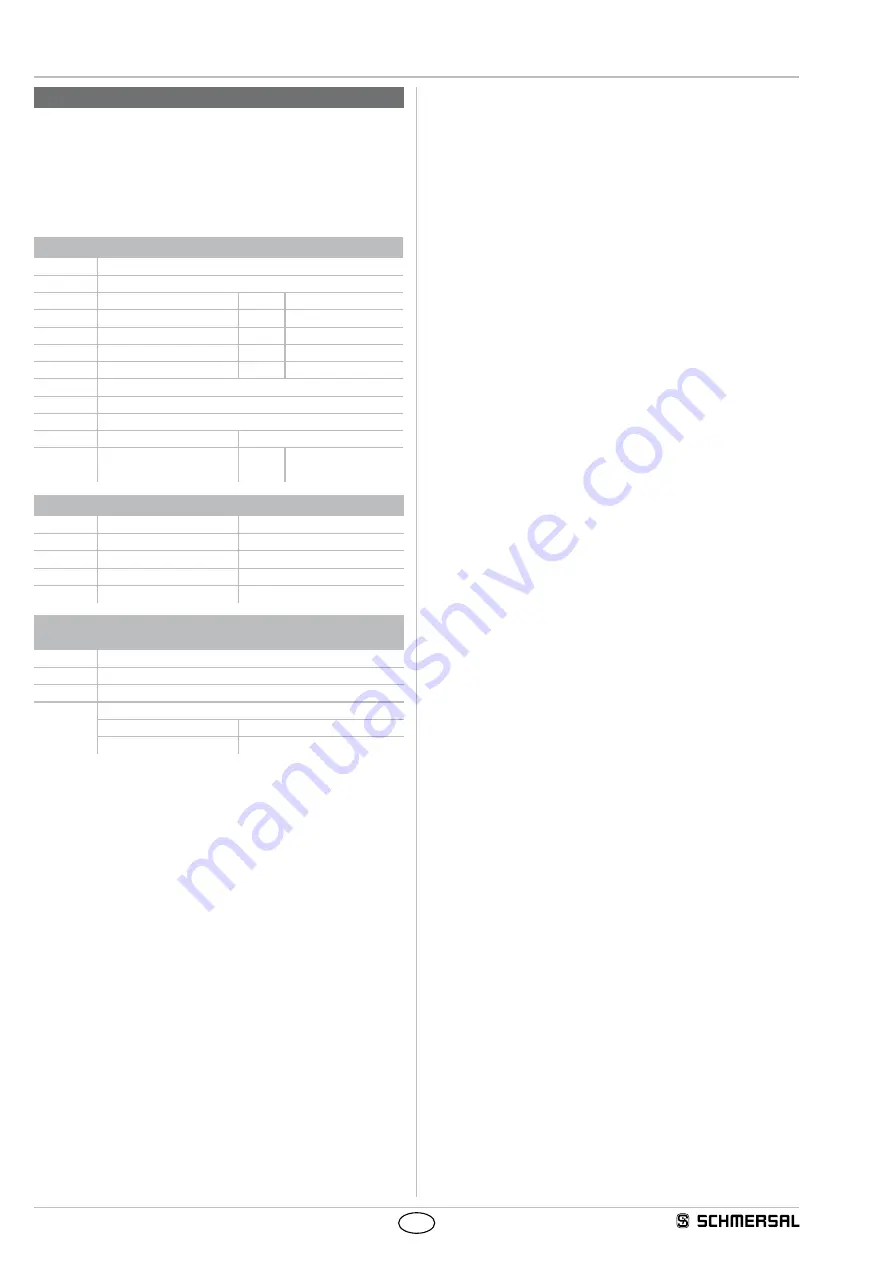

Application program 02

Prog_02: Two safety areas, visible from control area,

2 x individual sensors for safety area 1,

3 x individual sensors for safety area 2,

1x Emergency-Stop command device (variable sensors)

(CRC 006F)

Connection example

Terminal assignment of the digital inputs

I00

START / RESET for safety area 1 (SB1)

I01

START / RESET for safety area 2 (SB2)

I02 + I03

1.1 Sensor (SB1):

MSP 2 (Default value=0 0 0)

I04 + I05

1.2 Sensor (SB1):

MSP 3 (Default value=0 0 0)

I06 + I07

2.1 Sensor (SB2):

MSP 4 (Default value=0 0 0)

I08 + I09

2.2 Sensor (SB2):

MSP 5 (Default value=0 0 0)

I10 + I11

2.3 Sensor (SB2):

MSP 6 (Default value=0 0 0)

I12

Feedback for safety area 1 (SB1)

I13

Feedback for safety area 2 (SB2)

I14

---

I15

START / RESET

for I16 + I17

I16 + I17

Emergency stop

command device,

MSP 1 (Default value=0 A 1)

Terminal assignment of the outputs

Q0, Q0N

Stop 0 or Stop 1 (SB1)

with fail-safe timer T00

Q2

Stop 0 or Stop 1 (SB2)

with fail-safe timer T01

Q3

Stop 0 or Stop 1 (SB2)

with fail-safe timer T02

QR1

Stop 0 or Stop 1 (SB2)

with fail-safe timer T03

QR2

Stop 0 or Stop 1 (SB2)

with fail-safe timer T04

Terminal assignment of the signalling outputs

(optionally digital input)

Y0 (I00)

---

Y1 (I04)

---

Y2 (I12)

---

Y3 (I14)

Signalling output: error message / status indication:

Error messages

= ON

Warnings

= Flashing ON with 1Hz

Program description

The application program is based on two monitored visible safety areas.

1. Safety area (SB1)

The user has the option of connecting 2 individual sensors to the inputs

I02 to I05 in the first safety area. The connected sensors I02 to I05

switch off the outputs Q0/Q0N.

The condition START / RESET via the input I00 is permanently

assigned to the inputs I02 to I05.

The feedback for the safety area 1 is implemented via the input I12.

2. Safety area (SB2)

The user has the option of connecting 3 individual sensors to the inputs

I06 to I11 in the second safety area. The connected sensors I06 to I11

switch off the outputs Q2 and Q3, QR1 and QR2.

The condition START / RESET via the input I01 is permanently

assigned to the inputs I06 to I11.

The feedback for the safety area 2 is implemented via the input I13.