3

CSS 30S

CSS 300

Operating instructions

Safety sensor

EN

Rated impulse withstand voltage U

imp

:

0.8 kV

Rated insulation voltage U

i

:

32 V

Response time:

< 60 ms

Duration of risk:

< 60 ms

Safety outputs Y1/Y2:

NO function, dual-channel,

p-type, short-circuit proof

Rated operating voltage U

e1

:

24 VDC (-15% / +10%)

Voltage drop:

U

e

< 1 V

Leakage current l

r

:

< 0.5 mA

Related operating current l

e1

:

max. 0.25 A

Minimum operating current I

m

:

0.5 mA

Utilisation category:

DC-12, DC-13

Required rated short-circuit current:

100 A

Diagnostic output:

short-circuit proof, p-type

Rated operating voltage U

e2

:

24 VDC (-15% / +10%)

Voltage drop:

U

e

< 5 V

Related operating current l

e2

:

max. 0.05 A

Utilisation category:

DC-12, DC-13

Serial diagnostic

Operating current:

150 mA, short-circuit proof

Wiring capacitance for serial diagnostics:

max. 50 nF

2.6 Safety classification

Standards:

ISO 13849-1, IEC 61508

PL:

e

Control Category:

4

PFH:

3.6 x 10

-9

/ h

PFD:

3.95 x 10

-5

SIL:

suitable for SIL 3 applications

Service life:

20 years

3. Mounting

3.1 General mounting instructions

During fitting of the actuator and the sensor, the requirements

of ISO 14119, especially paragraph 7 must be observed!

The sensor enclosure must not be used as an end stop. The component

can be mounted in any position. The active surface of the safety sensor

and the actuator have to be opposite. The safety sensor must only be

used within the assured switching distances ≤ sao and ≥ sar.

The safety sensor and the corresponding actuator can be fixed using

the supplied M30 nuts (A/F 36). The max. tightening torque is 30 Nm

(CSS 30S) or 400 Ncm (CSS 300).

A concealed mounting is possible, however this reduces the switching

distance. The reduction will be lower, when the sensor and the actuator

protrudes a few mm.

The actuator has a slot in the active front surface. In confined spaces,

this slot can be used to fix the actuator by means of a screwdriver.

Safety sensor and actuator must be permanently fitted to the

safety guards and protected against displacement by suitable

measures (tamperproof screws, gluing, drilling of the screw

heads).

To avoid any interference inherent to this kind of system and any

reduction of the switching distances, please observe the following

guidelines:

• Minimum distance between two sensors:

CSS 30S: 50 mm

CSS 300: 100 mm

• The presence of metal chips in the vicinity of the

sensor is liable to modify the switching distance

• Keep away from metal chips

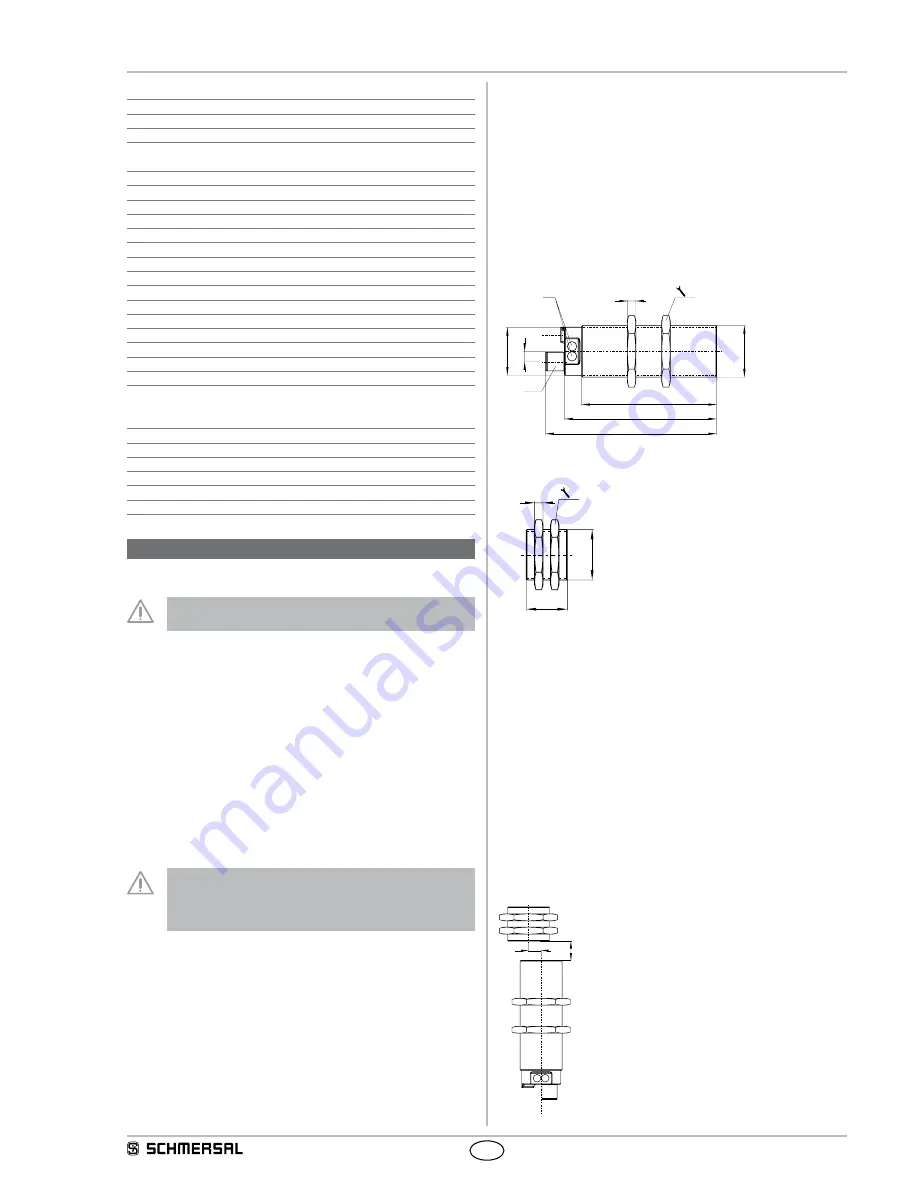

3.2 Dimensions

All measurements in mm.

Safety sensor

M3

0

x

1,5

78,5

99,5

88,5

6

5

Ø28

LED

M12 x 1

36

Actuator

24,5

M30x1,5

5

36

3.3 Adjustment

The LED of the safety sensor can be used as an adjustment tool.

The yellow flashing LED of a sensor signals that an adjustment of the

switching distance is required. Reduce the distance between the sensor

and the actuator, until the LED of the safety sensor is continuously lit

yellow.

The correct functionality of both safety channels must be checked by

means of the connected safety-monitoring module.

3.4 Switching distance

The graphs show the switch-on and switch-off points of the sensor

due to the approach of the actuator. The maximum misalignment of

the actuator with regard to the sensor centre is 9 mm. A concealed

mounting of the sensor and the actuator will reduce the switching

distance. (see “Mounting” part)

S

V