1

5

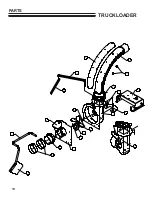

TRUCKLOADER

OPERATING

This machine has been designed for two methods of

vacuuming debris:

-

With the handle of the Intake Nozzle in the

operator’s hands, move the nozzle back and forth

in a sweeping motion over the debris

-

Rotate Intake Nozzle to lay sideways on the

ground. By placing the Nozzle in this position,

debris can be raked into the nozzle by an

operator.

While large amounts of debris can be vacuumed

quickly with this machine, caution must be taken to

avoid blocking the airflow into the Nozzle.

STOPPING THE ENGINE

When operation is complete or the unit needs to be

checked or a clog needs to be cleared:

1. Move the throttle to SLOW.

2. Set the engine and fuel lever to the OFF position.

3. Note: Impeller will continue to rotate for several

seconds after engine is stopped.

EXCESSIVE VIBRATION

Shut off the engine immediately if abnormal/excessive

vibration occurs. Remove spark plug wire. Find

the cause of vibration and repair it. Some possible

causes for excessive vibration are:

-

Damaged impeller

-

Loose impeller bolt

-

Loose impeller key

-

Lodged objects

CLOGS

To prevent clogs, do not overfeed, especially with

heavy wet material.

Pay attention to how full the debris receptacle is.

Overfilled debris receptacles cause material to back

up and get tightly packed in the discharge cute.

REMOVING CLOGS

If a decrease in suction is experienced, there may be

a debris blockage in the hose. Often a clogged hose

can be cleared by stretching the hose out straight with

the engine running. If the hose does not clear, you

will need to remove the hose. Before removing the

hose or attempting to clear a clog manually:

-

STOP the engine. Put the engine switch in the

OFF position.

-

Wait for the impeller to come to a complete stop.

-

Disconnect the spark plug wires so impeller

movement cannot accidentally start the engine.

Removing Clogs ( continued)

CAUTION SHOULD BE USED WHEN CLEARING

DEBRIS FROM INSIDE THE HOUSING. GLOVES

SHOULD BE WORN AS SHARP EDGES ON THE

IMPELLER OR IN THE DEBRIS MAY BE PRESENT.

Remove the Hose Assembly from the Inlet Flange

Assembly. With this removed, open the Inlet Flapper

and remove any debris that is clogging the housing.

Remove the Discharge Chute from the Transition

Discharge tube’s flange. With the Chute removed,

inspect the Transition Discharge part of the housing

and remove any debris clogging this area.

Reassemble removed parts, reconnect the spark plug

wire and resume operation.

NEVER TRANSPORT MACHINE

WHILE IT IS RUNNING

TRANSPORT

1. Shut off the engine and fuel valve.

2. Disconnect the hose from the power unit.

3. Remove the boom assembly from the frame (it

can stay with the hose.)

4. Remove the discharge chute.

5. Transport the hose/boom assembly and discharge

chute secured in the truck or trailer.

6. Do not exceed 30 mph. High speeds together with

rough roads can cause damage to the unit

OPERATION

Содержание LITTLE WONDER monster Truckloader 8143-06-01

Страница 21: ...1 2 5 4 3 6 9 11 10 12 13 14 15 17 16 19 8 20 21 18 7 19 TRUCKLOADER PARTS ...

Страница 23: ......