Magnetic Drilling Machine

Operating Manual

8

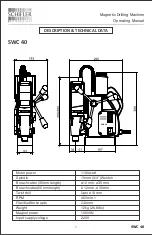

SWC 40

2. Disposal of grease: Follow the instructions given by the lubricant's

manufacturer.

1. Disposal of the old electrical equipment: Make sure you process the product

in accordance with EC Directive 2002/96/EC-WEEE, also known as Waste

Electrical and Electronic Equipment. In case of doubts or queries, contact the

Department of Waste Disposal.

CLEANING AND MAINTENANCE

2. Inspect the carbon brush and change it immediately if you notice that it is

worn out.

4. It is always the after-sales service department or the designated dealer who

cater to the maintenance of the drill machine.

1. Keep a close check on the bolt of the magnetic drill. It should not be loose and

the gap in the spindle should not be too large. The power cable of the drill

should be in a good condition. You must make sure that the machine is

maintained well.

3. The lubricating grease in the Gear Box should be changed by a professional

once you have used the drill for three months. Inspect well once the

professional finishes to double check that all the parts have been fully

lubricated.

7. Switch the machine off and unplug it from the main power socket before you

start the process of maintenance and cleaning.

When it comes to the process of maintenance, inspection and repair pertaining

to their electrical aspects, only a qualified electrician must be contacted to cater

to the task. The qualifications of these electricians change according to their

respective countries. They must follow the effective rules put in place when it

comes to processing, inspection and the maintenance of a Circuit Board in order

to avoid accidents.

5. The operator must clean the magnetic drill after finishing the work, scrub the

side where the drill slides while working and apply lubricating oil on the drill

for the machine to last longer.

6. Whenever you indulge in the process of cleaning the Drill with compressed

air, you must wear safety goggles and protective gloves to protect yourself

and the other people around you at the workstation.

ENVIRONMENTAL PROTECTION AND WASTE DISPOSAL

Содержание SWC 40

Страница 1: ...Magnetic Drilling Machine OPERATING MANUAL SWC 40 SWC 40 ...

Страница 15: ...Magnetic Drilling Machine Exploded View SWC 40 Motor complete Antriebseinheit 13 SWC 40 ...

Страница 22: ...NOTES Magnetic Drilling Machine Operating Manual SWC 40 SWC 40 ...

Страница 23: ...NOTES Magnetic Drilling Machine Operating Manual SWC 40 ...