Magnetic Drilling Machine

Operating Manual

17. The generation of the magnetic field affects devices such as watches, mobile

phones and pacemaker installed to regulate the heartbeat. Make sure that

the operator takes of the watch and keeps the mobile phone before

operating the drilling machine and doesn't have a pacemaker installed in

him.

12. Do not remove the drill if the spindle and the drill are in continuous motion.

Unplug the drill from the main power supply to change its gear and never

touch it with your bare hands.

13. Even when the equipment stops working, never use your bare hands to

remove the iron fillings after the drilling process as that can cause injuries.

10. Whenever the magnetic drilling machine is in use and is suspended either in a

vertical or a horizontal position, you must get it fixedwith a device that gets

attached to the equipment so that it doesn't come down falling caused by the

sudden loss of power of the magnetic base. When you choose to drill in an

upside-down position, always opt for a cooling method that is reasonable.

Say a frank NO to the option of Liquid Cooling method as liquid will easily

infiltrate into the equipment and result in leakage of electricity. Instead of

Liquid Cooling method, choose Mist Spray Cooling.

11. If a Supplier has provided or approved of the Parts and Tools, only then must

you use them as once installed on the equipment, they come with a

guaranteed usage safety.

15. Use the handle function of the drilling machine to move it from one place to

another instead of pulling the power cable.

16. Switch off the main power supply and unplug the drilling machine after the

usage. If this is not done and the spindle and the tool continue to rotate, then

do not let the operator remove the drill and replace the gear with his bare

hands. Make sure you practice this to avoid injuries.

9. Add a certain amount of coolant to the equipment whenever you replace the

drill. In case you notice a blockage, switch off the motor immediately.

However, you must leave the magnetic base power on. The logic behind this

process is that in case you shut down the power supply of the magnetic base

directly, it may result in the operator suffering from injuries. It will also harm

the motor because of the sudden loss of magnetic force of the magnetic

base.

14. While you use the magnetic drill on a particular workpiece, do not do the

process of welding on the same.

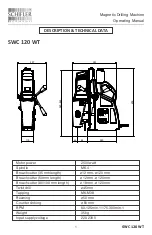

SWC 120 WT

7