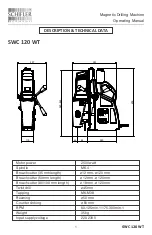

Magnetic Drilling Machine

Operating Manual

4 Apply cutting oil to the twist drill and workpiece. Always use cutting oil from

your dealer.

3 Ensure that the magnetic drilling unit is secure on the working piece.

5 Start the motor by pressing the green motor start button.

7 After the cutting is finished switch the machine off by pushing the red button.

6 Start bringing the twist drill to the workpiece but handle with care and do not

apply too much pressure. The drill has to find its way in to the material by

itself. It is not necessary to use a lot of pressure. Too much pressure will cause

damage and breakage.

5.4 SPEED SELECTION

It is recomednded to run the machine for diameter upto 35mm on speed 1-A (300

-1

-1

min ), for diameter above 35mm to 50 mm on speed 1-B (175 min ), for diameter

-1

above 50mm to 80mm on speed 2-A (125 min ) and for diameter above 80mm ot

120mm on speed, 2-B as shown.

Switch off the machine before changing the gear knob.

Warning:

2

1

B

A

-1

300 min

2

1

B

A

-1

125 min

2

1

B

A

-1

175 min

2

1

B

A

-1

80 min

Gear

HSS

Carbide

max.

Ф

1-A

-1

(300 min )

25mm

1"

35mm

1-3/8"

1-B

-1

(175 min )

45mm

1-3/4"

50mm

2"

2-A

-1

(125 min )

60mm

2-3/8"

80mm

3-1/8"

2-B

-1

(80 min )

100mm

4"

SWC 120 WT

12