19

Defective electrical connection cables

Electrical connection cables often suffer insulation dam-

age.

Possible causes are:

• Pinch points when connection cables are run through

window or door gaps.

• Kinks resulting from incorrect attachment or laying of

the connection cable.

• Cuts resulting from running over the connecting cable.

• Insulation damage resulting from forcefully pulling out

of the wall socket.

• Cracks through aging of insulation.

Such defective electrical connection cables must not be

used as the insulation damage makes them

extremely

hazardous.

Check electrical connection cables regularly for dam-

age. Make sure the cable is disconnected from the mains

when checking.

Electrical connection cables must comply with the regu-

lations applicable in your country.

Single-phase motor

• The mains voltage must coincide with the voltage spec-

ified on the motor’s rating plate.

• Extension cables up to a length of 25 m must have a

cross-section of 1.5 mm

2

, and beyond 25 m at least

2.5 mm

2

.

• The connection to the mains must be protected with a

16 A slow-acting fuse.

Only a qualified electrician is permitted to connect the

machine and complete repairs on its electrical equip-

ment.

In the event of enquiries please specify the following

data:

• Motor manufacturer

• Type of current of the motor

• Data recorded on the machine’s rating plate

• Data recorded on the switch’s rating plate

If a motor has to be returned, it must always be dis-

patched with the complete driving unit and switch.

or moved while sawing.

2

Only move the saw forwards.

3

Grip the saw tightly with both hands ensuring that one

hand is placed on the main handle and the other on

the front handle.

4

When using a guide rail, it must be fastened with screw

clamps.

5

Make sure the power cable is not placed in the sawing

direction.

Sawing

1

Place the front part of the machine onto the work piece.

2

Switch the machine on using the on/off switch (4).

3

Press the plunge-cut trigger (3).

4

Push the saw downwards to reach the sawing depth.

5

Push the saw forward evenly.

6

After finishing the sawing cut, switch the machine off

and move the saw blade upwards.

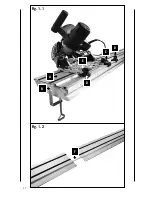

Plunge-cuts, Fig. 9

1

Place the saw onto the work piece.

2

Place the cutting indicator with the rear arrow (A) on

the marked plunge-cut position.

3

Switch the machine on and push the saw downwards

until you reach the set cutting depth.

4

Move the saw forwards until the cutting indication (C)

has reached the marked point.

5

After completion of the plunge-cut, move the saw blade

upwards and switch the saw off.

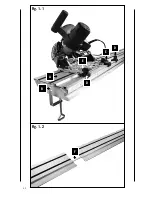

Cutting with rails (otional)

1

Place the machine in the guide rails. can be readjusted

using the hex driver included in the delivery, when

there is the risk of the adjusting screws releasing by

themselves.

2

Turn on the machine by pressing the on/off switch (4).

3

Press the dip trigger (3).

4

Press the saw downwards to reach the sawing depth.

During first use the rubber lip is sawn off and thus

splitter protection is guaranteed up to the saw blade.

5

Push the saw uniformly forwards.

6

Turn off the machine and tilt the saw blade to the top

when the saw cutting is complete.

Sawing with dust suction

Connect the suction hose to the exhaust nozzle - Ø 38

mm (12).

m

Electrical connection

The installed electric motor is completely wired ready for

operation.

The customer’s connection to the power supply system, and

any extension cables that may be used, must conform with

local regulations.

Important remark:

The motor is automatically switched off in the event of

an overload. The motor can be switched on again after a

cool ing down period that can vary.

Содержание PL55

Страница 12: ...12 Fig 1 1 A E B D D E Fig 1 2 F ...

Страница 21: ...21 ...

Страница 22: ...22 Fig 1 1 A E B D D E Fig 1 2 F ...

Страница 32: ...32 Fig 1 1 A E B D D E Fig 1 2 F ...

Страница 42: ...42 Fig 1 1 A E B D D E Fig 1 2 F ...

Страница 52: ...52 Fig 1 1 A E B D D E Fig 1 2 F ...

Страница 54: ......

Страница 55: ......

Страница 58: ......