Fire-resistant damper model BKA-Ü

Technical documentation

Installation in lightweight partition walls with metal posts

Construction subject to change

No return possible

Version: 2021-07-01 | Page 20

Dry installation with soft seal

BKA-Ü must be permanently suspended from the solid ceil-

ing on both sides of the wall (see page 24). Suspension an-

gle (pos. 38) for BKA-Ü is available as accessory at an extra

charge.

With an annular gap of 50 - 100 mm, the BKA-Ü must be

installed together with the firestop boards. Mounting of the

firestop boards after installation of the BKA-Ü (installation

dimension 210 mm) is possible starting with an annular gap

of about 100 mm.

For each BKA-Ü, a separate installation opening must be

provided.

The distance from one BKA-Ü to another must be at least

200 mm.

Depending on the wall thickness, the minimal distance to

adjacent components is, due to the design, at least approx.

103/115 mm from the ceiling and approx. 113/125 mm

from the wall. The actual minimum distance may slightly

differ from the distances mentioned therein and must be

executed and adapted as a function of the wall connection

type.

Further information to be considered: see page 7 Minimum

distances or projecting ends.

Soft seal system

Permissible soft seal system (provided on site):

Manufacturer Hilti

•

Firestop boards CFS-CT B 1S 140/50

•

Firestop coating CFS-CT

•

Firestop boards CP 673 PF

•

Firestop coating CP 673

•

Firestop sealant CFS-S ACR

In general, the specifications and processing guidelines of

the soft seal manufacturer (in particular the maximum seal

dimensions) must be observed.

Dimensions of the min./max. annular gap

*)

≙

max. seal dimensions according to the manufacturer's specifica-

tions Hilti

Figure 28: Example of installation in soft seal system

Wall thickness = 100 mm

*)

≙

max. seal dimensions according to the manufacturer's specifica-

tions Hilti

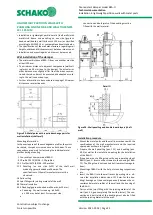

Figure 29: Metal stud frame plus required replacement parts

(for wall thickness = 100 mm)

Mounting information:

In the overlap area of the exchangeable profiles, they must

be riveted, crimped or screwed once on both sides. These

connections are only for fastening the individual metal pro-

files during mounting.

Sectional view for wall thickness = 100 mm

Figure 30: Installation in metal stud wall (wall thickness = 100 mm)