-6-

Electrical Adjustments

1. Receive the 50%-Whole Gray computer signal with

Computer1 [RGB]

mode.

. Enter the service mode.

3. Select group no. “

9

”, item no. “

92

” and change data

value to “

2

” to reduce the panel frequency.

4. Project only green light component to the screen.

5. Select group no. “

10

”, item no. “

1

” and change data

value to obtain the minimum flicker on the screen.

6. Project only red light component to the screen.

7. Select item no. “

0

” and change data value to obtain

the minimum flicker on the screen.

8. Project only blue light component to the screen.

9. Select item no. “

2

and change data value to obtain

the minimum flicker on the screen.

10. Select group no. “

9

”, item no. “

92

” and change

data value to “

0

” to reset the panel frequency.

,

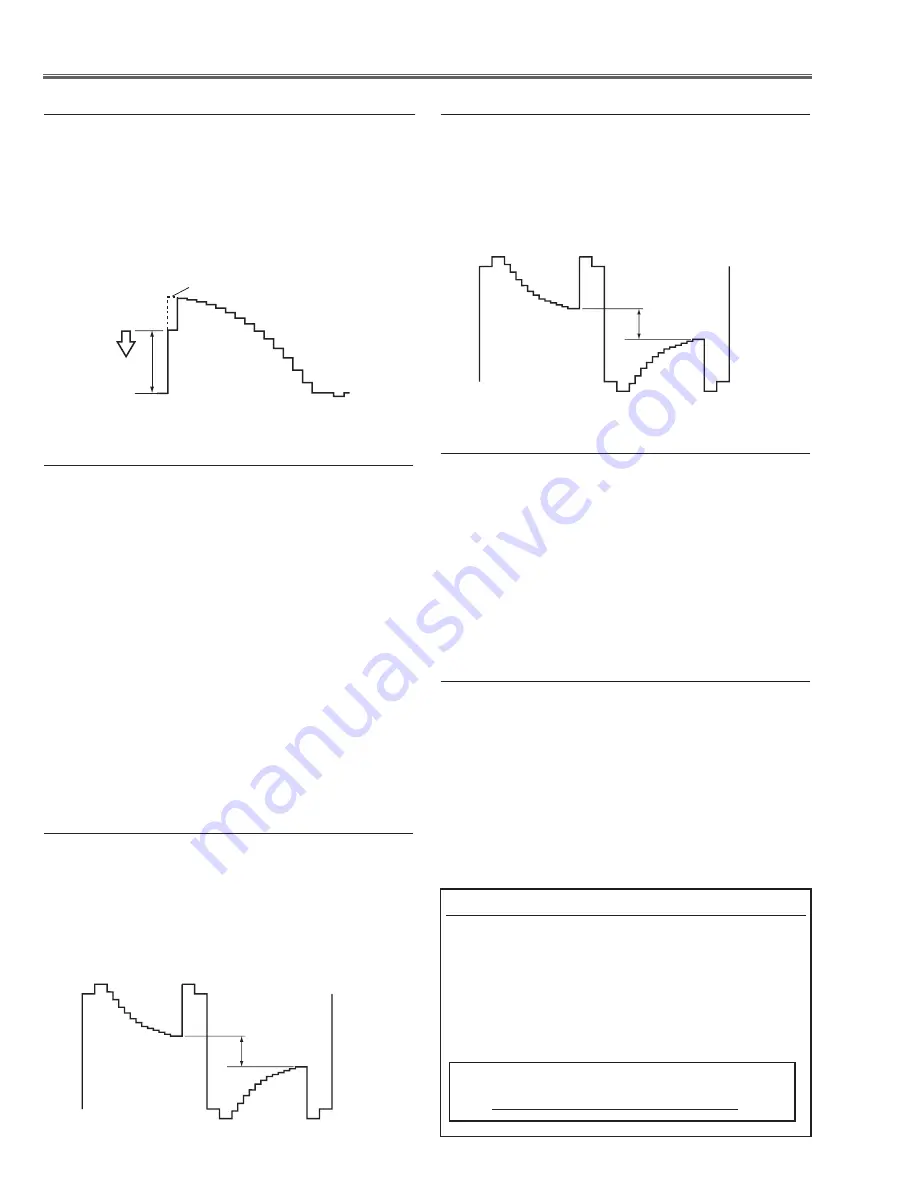

Common Center adjustment

1. Receive the 16-step grey scale computer signal with

Computer1 [RGB]

mode.

. Enter the service mode.

3. Connect an oscilloscope to test point “

tP_G1

” (+)

and chassis ground (-).

4. Select group no. “

9

”, item no. “

7

” and change data

value to adjust amplitude “a” to be

1.6

±0.1V.

(a)

white level

white level

.

50% White adjustment [PC]

1. Receive the 16-step grey scale composite signal with

Video [Video]

mode.

. Enter the service mode.

3. Connect an oscilloscope to test point “

tP_G1

” (+)

and chassis ground (-).

4. Select group no. “

103

”, item no. “

0

” and adjust the

amplitude “a” to be

minimum

by changing the Data

value.

(a)

White Level

m

Gain adjustment [Video]

1. Receive the 16-step grey scale composite video sig-

nal with

Video [Video]

mode.

. Enter the service mode.

3. Connect an oscilloscope to test point “

tP_G1

” (+)

and chassis ground (-).

4. Select group no. “

9

”, item no. “

7

” and change data

value to adjust amplitude “a” to be

1.6

±0.1V.

(a)

white level

white level

⁄0

50% White adjustment [Video]

1. Receive the 16-step grey scale composite video sig-

nal with

Video [Video]

mode.

. Enter the service mode, select group no. “

9

” item

no. “

6

” (Red) or “

8

” (Blue), and change Data values

respectively to make a proper white balance.

Confirm that the same white balance is obtained in

video and computer input.

⁄2

White Balance adjustment [Video]

Note On White Uniformity Adjustment

If you find the color shading on the screen, please

adjust the white uniformity by using the proper

computer and “Color Shading Correction” software

supplied separately.

The software can be ordered as follows;

CoLoR SHAdING CoRRECtIoN Ver. 4.00

Service Parts No. 645 075 9611

1. Receive the 16-step gray scale computer signal with

Computer1 [RGB]

mode.

. Enter the service mode, select group no. “

9

” item

no. “

6

” (Red) or “

8

” (Blue), and change Data values

respectively to make a proper white balance.

Confirm that the same white balance is obtained in

video and computer input.

⁄1

White Balance adjustment [PC]

Содержание PLC-XL45

Страница 27: ... 27 40 2 0 3 40 40 2 40 40 Electrical Adjustments MAIN BOARD Test Points and Locations ...

Страница 52: ... 52 BA7078 Sync Separator IC5301 IC Block Diagrams BA9743 DDC Control IC5651 ...

Страница 53: ... 53 IC Block Diagrams L3E01060 LEVEL SHIFT IC2501 IC2531 IC2561 FA5502 P F Control IC621 ...

Страница 54: ... 54 IC Block Diagrams L3E06150 D A S H IC501 IC531 IC561 L3E07110 LCD Driver Gamma Correction IC401 ...

Страница 55: ... 55 IC Block Diagrams M62334 D A IC3571 NJW1141 Audio Control IC5001 ...

Страница 56: ... 56 IC Block Diagrams STR Z2156A Power Switching IC631 uPD64012 Video Decoder IC101 ...

Страница 83: ...KZ6 XL4500 83 Mechanical Parts List L11 L08 L12 L16 L04 L17 L10 L06 L03 L05 In the Optical Unit L08 ...

Страница 85: ...KZ6 XL4500 85 Mechanical Parts List ...

Страница 86: ... KZ6AC Dec 2007 DC 350 Printed in Japan SANYO Electric Co Ltd ...

Страница 98: ...A10 SCH_KZ6AC 1 3 4 5 6 7 8 9 10 11 1 13 14 15 16 A B C D E F G H I J K L A B C D E F G H I J K L NO DATA ...