2

Installation

Valve and actuator are supplied already as-

sembled by the manufacturer.

For more details on the actuator used,

please refer to the appropriate mounting

and operating instructions.

2.1

Mounting position

The valve can be mounted in any position.

However, the limitations due to the actuator

used must be strictly observed.

CAUTION!

The valve must be installed free of stress and

free of excessive vibrations. If necessary,

support the pipelines near the connections.

Do not install supports on the valve or on the

actuator. Thoroughly flush the pipeline prior

to installation of the valve.

Pipeline routing

To allow the control valve to work properly,

the pipeline upstream and downstream of

the valve must be straight and free of ob-

structions for a length of at least 6 times the

pipe diameter (DN). Contact SAMSON if

this length cannot be met during installation.

Clean out the pipeline thoroughly prior to in-

stalling the valve.

2.2

Arrangement of control valve

Depending on the task to be performed, the

control valve is arranged as illustrated in

Fig. 3.

How the plugs are arranged for mixing or

diverting valves is specified on the label at-

tached to the valve body.

Fail-safe action: Valve shuts off the heating

medium supply or opens the supply of cool-

ing medium.

2.3

Strainer and bypass

We recommend installing a SAMSON

Type 2 N Strainer upstream of the valve,

and upstream of both ports for mixing

valves.

In addition to a bypass line, shut-off valves

should be installed both upstream of the

strainer and downstream of the control valve

so that the plant need not be shut down for

maintenance routines.

Installation

6

EB 8135/8136 EN

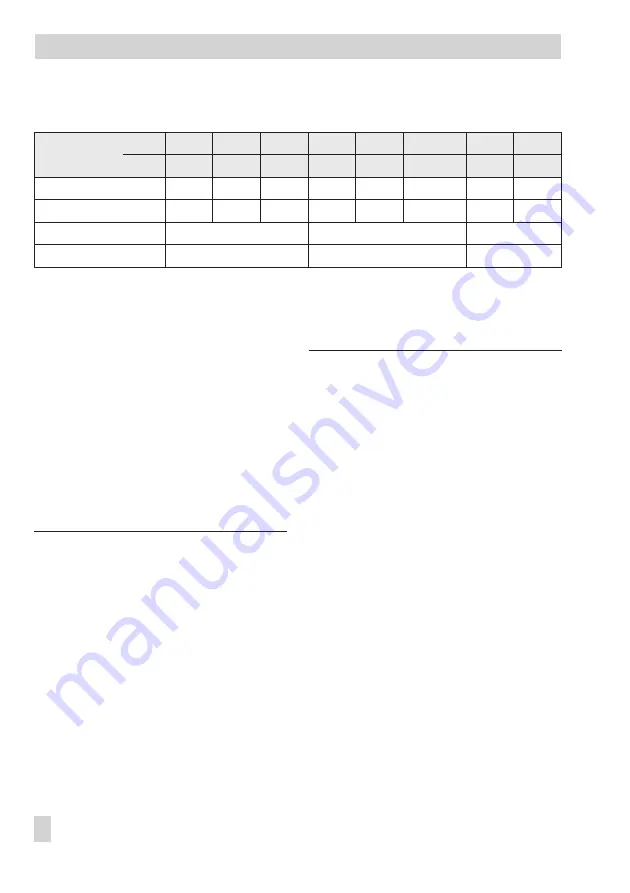

K

VS

and C

V

coefficients, seat diameters and travel

Nominal size

DN

15

20

25

32

40

50

65

80

NPS

½

¾

1

–

1½

2

2½

3

K

vs

coefficients

4

6.3

8

16

20

32

50

80

C

v

coefficients

5

7.5

9.4

–

23

37

60

94

Seat diameter

mm/in

24 mm · 0.94”

40 mm · 1.57”

65 mm · 2.56”

Travel

mm/in

15 mm · 0.59”

15 mm · 0.59”

15 mm · 0.59”