EB 8140 EN

31

Servicing

14. Pull all the packing parts out of the pack-

ing chamber using a suitable tool. Clean

the packing chamber thoroughly. Renew

the packing.

15. Slide the plug/actuator stem (2) into the

valve bonnet (3).

16. Carefully slide the packing parts over the

plug/actuator stem into the packing

chamber using a suitable tool. Keep the

correct sequence:

−

Spring (4.5)

−

Washer (4.3)

−

V-ring packing (4.4)

17. Place the top slip washer (5.2) into the

actuator base (5).

18. Push the threaded bushing (4) into the

actuator base (5). Make sure that the

O-ring (5.3) is correctly seated in the

threaded bushing.

19. Place the bottom slip washer (5.2) on the

valve bonnet (3).

20. Screw the threaded bushing (4) together

with the actuator base (5) over the plug/

actuator stem (2) onto the valve bonnet

(3).

Tighten the threaded bushing only to the

point where the actuator base (5) can

still rotate on the slip washers (5.2).

21. Screw tight the retaining screw (4.2) at

the side to fix the threaded bushing in

place.

22. Place the spring (9) together with the

washer (9.1) onto the actuator base (5).

23. Slide the piston (8) with piston ring (8.1)

over the plug/actuator stem (2).

24. Place on the O-ring (8.2) and washer

(12).

25. Tighten the nut (11) intended for fasten-

ing the piston, while holding the plug/

actuator stem (2) stationary at the flat

-

tened part with an open-end wrench.

26. Fasten the travel indicator (10).

27. Put on actuator housing (7) and dome

(7.1) and fasten them tight onto the actu-

ator base (5) by tightening the top

screws (6) gradually in a crisscross pat-

tern.

28. Replace the body gasket (3.1). See sec-

tion 7.1.

29. Place the valve bonnet (3) with plug (2)

onto the body (1).

30. Tighten the body nuts (1.1) gradually in

a crisscross pattern. Observe tightening

torques.

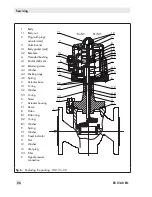

7.3 Tightening torques

Table 4:

Tightening torques for body nuts

(1.1)

Valve size

Tightening torque

DN 15 to 25 (M10)

30 Nm

DN 32 to 50 (M12)

50 Nm

DN 65 and 80 (M16)

100 Nm