2

853 822 R. 03/23

SAMOA Industrial, S.A. · Pol. Ind. Porceyo, I-14 · Camino del Fontán, 831 · 33392 - Gijón - Spain · Tel.: +34 985 381 488 · www.samoaindustrial.com

2023_03_06-16:00

EN

This pump can be operated in potentially explosive atmospheres

(ATEX). Directive 2014/34/EU of the European parliament establishes

essential health and safety requirements for the use of devices and

protective systems in these atmospheres and allows the technical

expression of the requirements contained therein to fall within the

harmonized European norms. Samoa Industrial S.A has followed a

procedure whereby it demonstrates the conformity of the product that

accompanies this manual with these requirements. This process has

consisted of the preparation and subsequent deposit of the required

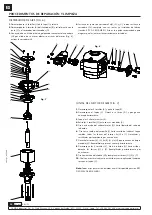

In the pump that accompanies this manual you should locate a label

with the following information included (do not use it in ATEX if you do

not incorporate it):

Ex:

indicates that it is possible to use this pump in a potentially

explosive atmosphere.

h:

indicates that it refers to the standard 80079-36.

IIB:

indicates the group of the equipment, in this case destined to be

used in explosive atmospheres of gas, except mines or when the typical

gas is hydrogen (in the directive, cat. 2G zone 1).

T4:

indicates the temperature class for group II. In this case, the class is

T4 (<= 135ºC), which takes into account the maximun temperature

that pump´s surface could reach when oil’s one is 70ºC (maximum

allowable value stated by this manual) and several hours of dry running

overheating occurs.

Directive part

2014/34/EU

Standard part

UNE-EN ISO 80079-36:2017

ATEX MARKING

CAREFULLY READ THE INSTRUCTIONS AND WARNINGS BEFORE STARTING TO OPERATE THE EQUIPMENT

!

technical documentation in the notified body mentioned in the

declaration of conformity together with an internal control of

the production.

The devices intended for use in this type of atmosphere must have a

specific marking that is an essential tool for the end user for the correct

location and use of the pump. Next, the content of the marking

incorporated by these pumps suitable for ATEX will be explained.

Remember that you should never use a pump that is not marked with

this label in potentially explosive atmospheres.

Gb:

indicates the EPL of the pump.

In addition, the marking includes the reference number of the technical

documentation that has been deposited with the notified body (see

declaration of conformity), followed by the letter “X”.

X:

indicates that there are special conditions of safe use that are

transmitted through this instruction manual to the end user, which in

this case are:

•

Ambient temperature for which the pump is intended:

-20ºC

≤

Tamb

≤

50ºC

•

Maximum surface temperature of the pump is dependent on the

temperature of the oil to be pumped, which should never exceed

70ºC, or the ambient one (whichever is greater).

•

A grounding cable with a clamp is included, which must be placed

firmly and stably and protected on a conductive element of the

installation, foreign to the pump and connected to the ground.

Zones defined by group II (gas): suitable for zone 1.

•

Zone 1:

areas in which explosive atmospheres caused by mixtures

of air and gases, vapours or mists are likely to occur in

normal operation.

ZONES OF USE OF ATEX PUMPS

ATEX INFORMATION