5

R. 03/23 853 822

SAMOA Industrial, S.A. · Pol. Ind. Porceyo, I-14 · Camino del Fontán, 831 · 33392 - Gijón - Spain · Tel.: +34 985 381 488 · www.samoaindustrial.com

2023_03_06-16:00

EN

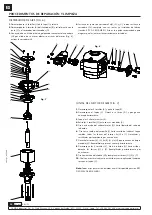

Please see figure 4, a typical installation shown with all the recommended accesories for the pump to operate correctly.

NOTE:

The compressed air supply must be between 30 and 170 psi (2 - 12 bar), and 80 to 100 psi is ideal.

K

I

L

A

B

C

D

E

J

F

G

H

TO OIL

CONTAINER

Fig. 4

POS. DESCRIPTION

PART. NO

A

Ball Valve, Low Pressure

239004

B

Filter/Regulator

241001

C

Air hose

247710

D

Quick coupling

251438

E

Connection nipple

255338

F

Pump

535530

G

Pressure Relief Valve

609008

H

Oil hose

946605

I

Ball Valve, Medium Pressure

950300

J

Wall bracket

360139 / 360140

K

Oil suction hose

945724

L

Ball Valve, Low Pressure

945567

TROUBLESHOOTING

SYMPTOMS

POSSIBLE REASONS

SOLUTIONS

The pump is not working or there is

no oil delivery.

Not enough air supply pressure.

Increase the air supply pressure.

Some outlet line component is clogged or closed.

Clean or open the outlet circuit.

The pump begins to operate very

fast.

The tank is empty or the oil level is beneath the

suction tube inlet.

Fill the tank or lower the suction tube until you

reach to the oil level.

The pump keeps on operating

although the oil outlet is closed.

There is an oil leakage in some point of the outlet

circuit.

Verify and tighten or repair.

Oil leakage through the air outlet

muffler or the leakage warning hole

on the pump body.

Oil has by-passed to the air motor caused by worn or

damaged seal.

Replace the seal. Check if the pump piston is scratched.

If so, replace the air piston assembly.

Air leakage through the air outlet

muffler.

Damaged or worn piston O ring.

Replace O Ring.

The air seal of the inverter assembly is damaged or

worn.

Replace the air seal.

Damaged or worn spool seals.

Replace the seals.

Oil output too low or diminishes

over time.

Contamination in the foot valve.

Remove and clean. Replace if damaged.

Contamination in the upper valve.

Remove and clean. Replace if damaged.

The exhaust felt is clogged by compressed air dirt or

lubricant.

Replace the muffler felt.

CLEAN THE MUFFLER (FIG. 5)

1.

Unscrew and remove the plug (C).

2.

Remove the muffler diffuser (B).

3.

Replace the felt (A) with a new one.

4.

Replace the diffuser (B) together with the new felt (A).

5.

Replace the plug (C).

REPAIR AND CLEANING PROCEDURE

WARNING

: Before starting any kind of maintenance or repair,

disconnect the compressed air supply and open a downstream

valve to relieve the oil pressure.

During the assembly, ensure to apply grease to all the seals.

!

Fig. 5

A

B

C

Vuelva a colocar el difusor (B) junto con el nuevo fieltro (A).

TYPICAL INSTALLATION