6

853 831 R. 02/20

SAMOA Industrial, S.A. · Pol. Ind. Porceyo, I-14 · Camino del Fontán, 831 · 33392 - Gijón - Spain · Tel.: +34 985 381 488 · www.samoaindustrial.com

2020_02_05-09:30

EN

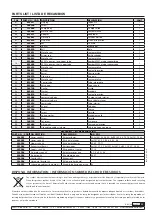

Fig. 6

21

22

18

15

14

24

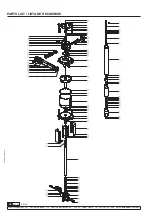

Fig. 5

22

24

25

26

27

25

14

28

1.

Unscrew bolts (24).

2.

Remove exhaust assembly (22).

3.

Unscrew the bolts (14) and remove the cap (28).

4.

Remove the felt (25).

5.

Remove the felt (27) and deflector (26).

6.

Remove the bottom felt (25) and replace it with a new one.

7.

Put back the deflector (26).

8.

Insert the screws (24) and then a new felt (27). If not in this order,

it could be tricky to insert the screws.

9.

Put a new felt (25).

10.

Put back the cap (28) and its screws (14).

11.

Ensuring the screws (24) stay into the muffler (22), put said muffler

on the motor and fix it with said screws.

12.

It is also available a whole muffler assembly kit (539005),

with replaces the old one just operating the screws (24).

REPAIR AND CLEANING PROCEDURE

WARNING!

BEFORE STARTING ANY KIND OF MAINTENANCE OR REPAIR:

•

DISCONNECT THE COMPRESSED AIR SUPPLY AND OPEN THE VALVE TO

RELIEVE GREASE PRESSURE. THE PUMP IS ABLE TO STORE

ULTRA HIGH

PRESSURE

, SO EXTREME PRECAUTIONS MUST BE TAKEN.

•

HEAVY WEIGHT EQUIPMENT: BE SURE TO FIX THE PUMP IN A STABLE

POSITION, USING THE UPPER EYE-BOLT WITH A LIFTER OR SOME STRONG

GRIPPING DEVICE (I.E. A VISE).

!

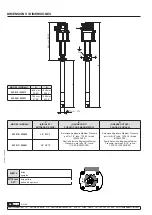

SEPARATE THE AIR MOTOR FROM THE PUMP (FIG. 4)

1.

Use some kind of lifter/support to manipulate and place the pump

in a vertical and stable position. For instance, both upper eye-bolts

(1) for lifting/hanging the motor and a vise for gripping the body/

tube (63/74) can be used.

2.

Take away both protective shields (46) by their bolts (90).

3.

Ensure the grease oulet valve is open, connect air and carefully

increase the pressure just until the pump starts to cycle in order to

get the connecting nut (50) a middle to low position of the stroke.

Now disconnect the air and make sure the pump is discharged,

with no internal pressure (grease outlet open).

4.

Unscrew the 4 bolts (62).

5.

Now the connecting nut (50) can be unscrewed from the lower

rod by spinning the whole motor counterclockwise. Warning! The

lowers get now free from the motor, so make sure the pump tube

is supported/fixed prior to separating the motor.

CLEAN THE MUFFLER (FIG. 5)

AIR DISTRIBUTOR (FIG. 6)

1.

Unscrew the bolts (14) and remove the cap (15).

2.

Ensuring the screws (24) remain into the muffler (22), unscrew

them and take away the muffler. Take away the o-ring (21).

3.

Strike gently with a plastic tool through exhaust side of

the motor to remove the spool valve (18).

4.

Replace the spool (18) by a new one with its seals factory

installed (kit 539006). This is strongly recommended in

order to ensure the correct assembly of the seals.

1

46

ATEX: periodically clean dust

deposits in the rod and upper

packing by removing shields

(46).

90

49

50

47

63

62

74

Fig. 4